Turkish Aerospace Industries, Inc. (TAI) has become Turkey’s center of technology in design, development, modernization, manufacturing, integration and life cycle support of integrated aerospace systems, from fixed and rotary wing air platforms to UAVs and satellites.

In order to implement its already considerable machine tools fleet, in 2012 TAI began the search for a cutting and milling centre to profile special carbon fiber sandwich panels for civil and military aviation and specifically for routing, cutting and milling of Boeing 787 rudders and elevators and the Airbus A350 flaps.

The mix of TAI needs with Belotti SpA proven experience in milling of composite materials and waterjet cutting led to a proposal involving the use of both technologies for the simultaneous processing of the work piece. Furthermore, to solve the long standing problem of the purchase, maintenance and storage of expensive aeronautic fixtures, TAI requested the universal vacuum fixture system.

Belotti S.p.A. taken up this challenge and submitted to TAI an engineering masterpiece: a 5-axis machining center model MDL 14 meters long and 4 meters width equipped with two independent gantries: the first one equipped with a 22 kW electrospindle and the second one with a hydroabrasive waterjet head connected to a 4100 bar pressure intensifier.

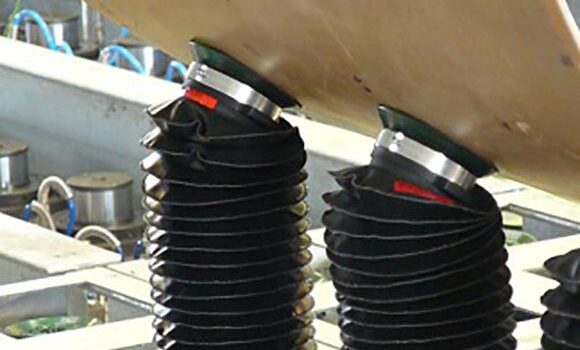

Another strong point of the machining center is the 10 x 4 m table with 260 active end effectors distributed on its surface, capable of automatic positioning accordingly to the real shape of the workpiece. To learn more, visit the page dedicated to UVF technology.

From the installation of the machining centre up to now, the customer has express his full satisfaction for both functionality of the milling center and customer care, basic conditions for a cooperation between our companies in the near future.

To learn more about TAI please visit: www.tai.com.tr

Click here to see the video

en