15 May 2023

The two companies strengthen the multi-year technological partnership with the implementation of Siemens NX software.

Siemens has always been a strategic technological partner for Belotti SpA, highly capable to understand the specific production needs and to support Belotti along its business growth and innovation path.

Over the years, the application of Siemens numerical controls on Belotti cnc machining centers for the management of milling and trimming operations, has led the company to develop high-end technological solutions for advanced materials’ processing (such as composites, light alloys, resins and plastics), taking advantage of the digital functions for a better optimization of the whole production cycle.

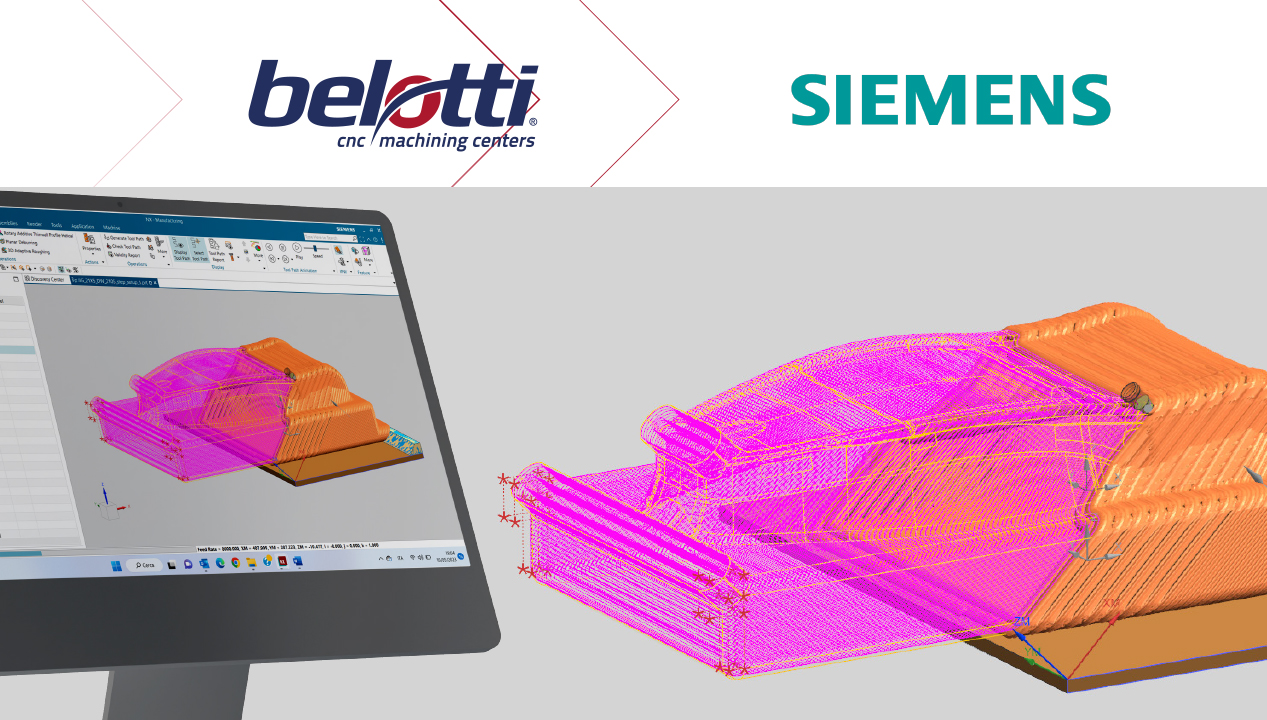

After the adoption of Sinumerik One software on Belotti cnc centers, the collaboration between the two companies has recently been consolidated with a new partnership signed with Siemens Digital Industry Software for the adoption of Siemens NX, an integrated end- to-end software for 3D printing capable of managing the entire CAD/CAM/CNC chain through a single platform.

“We are really pleased to announce the partnership with Siemens for the use of NX on our BEAD machines for large-scale 3D printing and milling,” says Alberto Riganti, Belotti S.p.A. Additive Manufacturing Specialist. “Siemens NX is a complete and advanced CAD/CAM software, which can be perfectly integrated with the Sinumerik One numerical control used to manage our cnc machining centres: this solution allows the operator to apply various deposition strategies, even the most complex ones, exploiting the 5 axes of the machine, and therefore all its potential. Thus, it’s possible to program single-wall deposition paths on planar printing surfaces – with or without internal reinforcement structures – as well as to program multi-perimeter paths, even on ‘non-compliant’ three-dimensional or helical surfaces, in order to avoid interruptions of the printing flow. The operator can optimise the hybrid production process, easily modifying complex geometries in the CAD environment and subsequently defining, in the CAM environment, the quantity of excess material to be printed, necessary for subsequent milling, so as to minimise the consumption of raw materials, saving time and production costs”, continues Riganti.

“The combined use of Siemens Sinumerik One and Siemens NX softwares allows for a precise simulation of the production process, not only by verifying the adhesion between neighboring layers and the quantity of material available for milling, but also by displaying the programmed deposition paths and checking collisions, thanks to the possibility of creating a three-dimensional model of the machine”, concludes Riganti.

The combination of Sinumerik One and Siemens NX softwares also allows, via the Digital Twin function, to simulate machines or machines’ systems by creating the respective digital twins, ensuring development times optimisation.

The implementation of Siemens NX software on Belotti BEAD hybrid machining centres has been completed with the technical and training support of ATS Team3D – the Italian division of ATS Global -, a provider of independent solutions for the smart digital transformation. ATS Team 3D is Siemens Digital Industry Software’s partner, specialised in sales and trainings on CAD, CAM, CAE, PLM, MES, MOM and IoT solutions, and a consultant company able to assist customers in the delicate task of innovating business processes and redefining productivity.

ATS Team3D is today the only Italian company that can cover the entire digitalisation flow, from design to product engineering and production.

“We at ATS Team3D, partner of Siemens for CAD – CAM – CAE – PLM and MES solutions, are happy to be an active part of this partnership, which represents the perfect example of how different skills employed in a single project bring tangible value to the market,” says Marco Riva, Manufacturing Specialist of ATS-Team3D – Italian division of ATS-Global.

“Thanks to the partnership with Belotti, who believed in the end-to-end solution provided by Siemens NX, it was possible to manage Additive Manufacturing technology applied to Belotti machining centres. We started with the preparation of the 3D model and then generated the deposition paths in the NX CAD/CAM solution. Tests and result verifications were carried out directly at Belotti HQ in Suisio (BG – Italy) on Belotti machines equipped with CEAD extruders. In addition, it was possible to simulate the ISO programme by verifying the entire machine kinematics in a digital environment.”

BELOTTI BEAD: ADDITIVE AND SUBTRACTIVE MANUFACTURING IN ONE MACHINING CENTER.

Born from the partnership between Belotti and the Dutch company CEAD, BEAD is the hybrid technology that integrates large-scale 3D printing and milling processes into a single machining center allowing for the production of models and production tools (moulds, plugs and autoclave toolings) through the use of different materials, from commodity to high performance fiber reinforced polymers.

BEAD exploits the best of both worlds combining the speed and creative potential of 3D printing with the precision and reliability of a cnc center in a single system. Through the integration of a CEAD extruder for additive manufacturing (of variable dimensions and capacity) in a Belotti 5-axis CNC machining center, BEAD allows the production of parts that are sufficiently oversized to be finished to the required tolerances with times and raw materials consumption lower than traditional methods.

BEAD solution can be possible in different configurations with variable build volumes, extrusion outputs and printing orientations, finding application in many industrial sectors: aerospace, automotive, marine, design and thermoforming.

Discover more on BEAD webpage.