18 March 2025

Belotti ARC – Automatic Riveting Cell, is a first-on-the-market integrated system, designed in partnership with Cosberg to automatically manage multiple types of Rivets and Time-Sert® with a single device.

This new revolutionary robotic cell features an under-patent riveting head designed for the rapid, automated application of the entire range of Time-Sert® inserts and Rivets of different diameters on composite frames and components across multiple industries – including automotive and aerospace – a task traditionally performed manually by the operators.

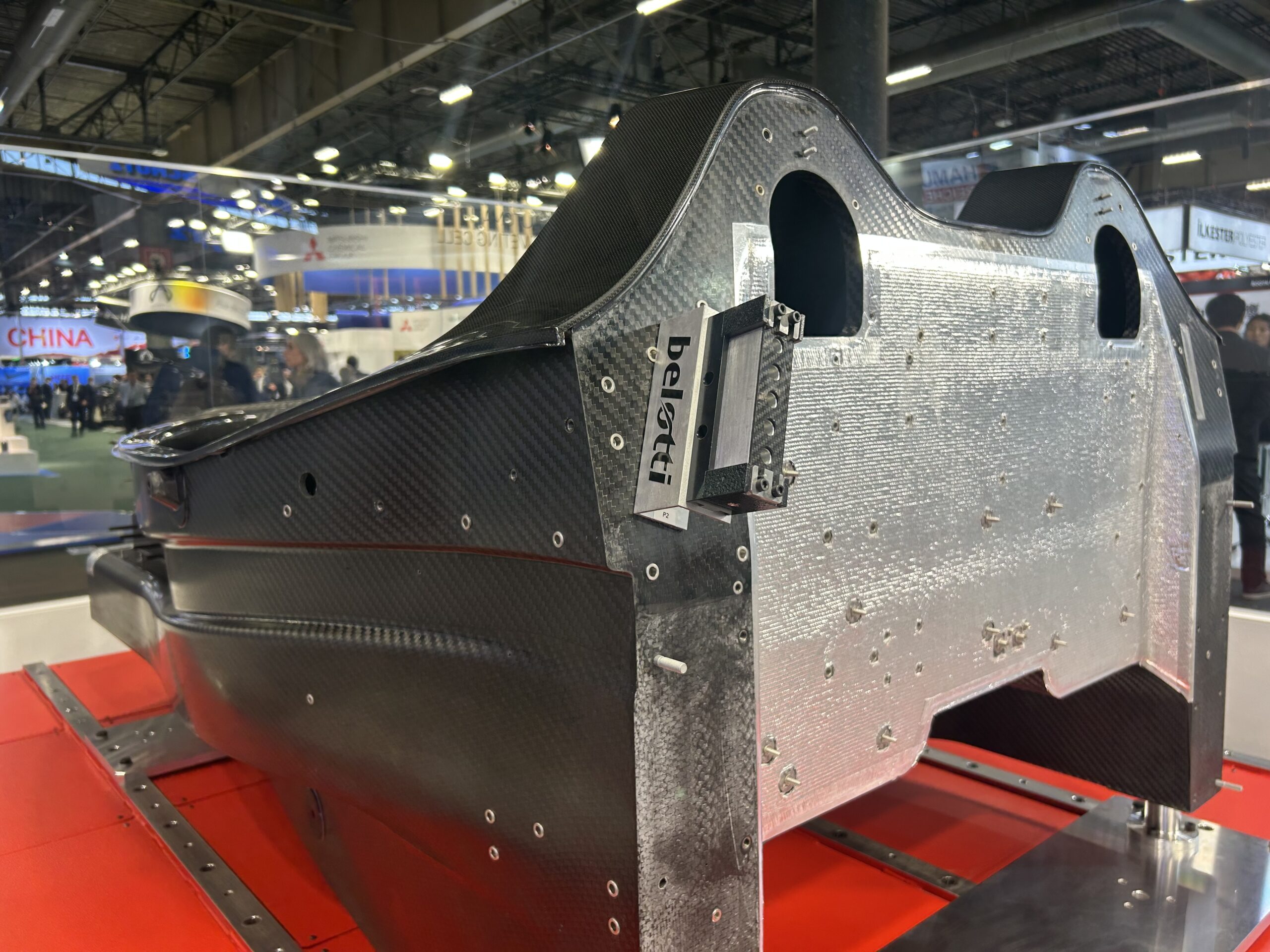

Many parts made of composite materials, including frames, monocoques, doors, roofs, and structural elements for the automotive sector, and wings and various aircraft components, are characterized by thin thicknesses that do not allow for sufficiently strong surfaces to insert fasteners necessary to ensure the assembly of various elements together.

Belotti ARC enables a precise application of key elements, ensuring a one-of-a-kind fast, flexible, and under-controlled execution.

A strategic partnership with Cosberg

Belotti ARC is the result of a strategic partnership with Cosberg, leveraging over 40 years of expertise in developing tailor-made solutions to automate the assembly and production processes (from mechatronic modules to fully automated machines). The system features a patent-pending riveting head that allows the automatic application of the entire range of Time-Sert® inserts and Rivets without requiring a head change, ensuring maximum efficiency and adaptability.

This partnership stems from a shared commitment to addressing the growing complexities of industrial production, particularly in sectors that demand cutting-edge technology and precision, such as aerospace and automotive.

Designed and refined over two years, Belotti ARC incorporates extensive research and innovative engineering to deliver a solution that combines efficiency, precision, and automation.

Belotti ARC took the stage at JEC World 2025: the official unveiling and presentation

Belotti ARC – Automatic Riveting Cell was officially launched and showcased during daily live demos at JEC World expo in Paris, offering visitors a firsthand experience of its capabilities and marking a significant milestone in composite machining and assembly automation.

The launch was also a key highlight at the Composite Exchange Conference “Streamlining Carbon Fiber Chassis Production with Automated Machining and Time-Sert Application”, held on March 4th at Agora 6, where Eng. Davide Seletti (CEO & General Manager of Dallara Compositi) and Loris Valsecchi (Belotti Sales Director) explored how automated machining and Time-Sert® applications are revolutionizing carbon fiber chassis production.

Key Features & Technology

Belotti ARC – Automatic Riveting Cell features:

- COMAU 6-axis Anthropomorphic Robot, payload 170 kg

- Compact, under-patent floating head by Cosberg

- Four-position rotary tables: from 1 to 2 tables for a modular configuration

- Siemens Sinumerik ONE CNC equipped with Run MyRobot

- Automatic feeding system for Rivets and Time-Sert® inserts

Main Benefits

This new technology represents a significant leap forward in optimizing composite material machining and assembly processes.

The main benefits can be highlighted as follows:

- One Head, Multiple Inserts: Rivets and Time-Sert® inserts of different diameters are managed automatically by a single device.

- Maximum Flexibility & Reachability: the anthropomorphic robot emulates the flexibility of the human wrist, enabling access to even the most challenging areas.

- Easy & Intuitive Programming: ISO programming language for seamless operation.

- Quality without Compromise: the advanced, fully electronic system enables precise control of all parameters.

- Precision under Control: real-time process tracking and feedback for unmatched accuracy.

- Redefining Productivity: faster, more flexible, and cost-effective fastening technology.

Get a closer look at this ground-breaking technology and its main benefits in our latest video.

Contact us at sales@belotti.com to learn more about the technical features and application potential of this new technology.