CSRS

Caterpillar Stack Routing System

Description

Machining centers manufacturers are constantly engaged in the research of a solution for milling of aluminium stack sheets, to satisfy specific Customers’ requests.

Machining centres worldwide market offers several solutions, thus underlining the fact that the evolution is still in progress.

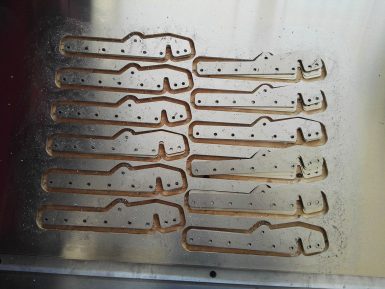

The high productivity of this technology, that sometimes competes with cutting, guarantees low costs and the advantage of an excellent flexibility. Furthermore, it is possible to machine piece depths from few tenths to some dozen of millimeters. This avoids the penetration of the coolant among the sheets, preventing part damages and the need of further washing of the final piece, also avoiding the inclusion of chips between components that could leave marks on the surface.

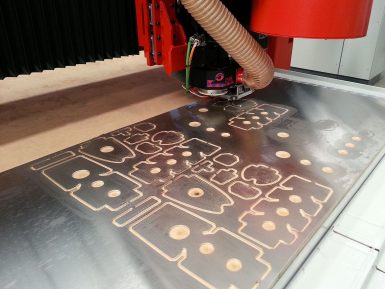

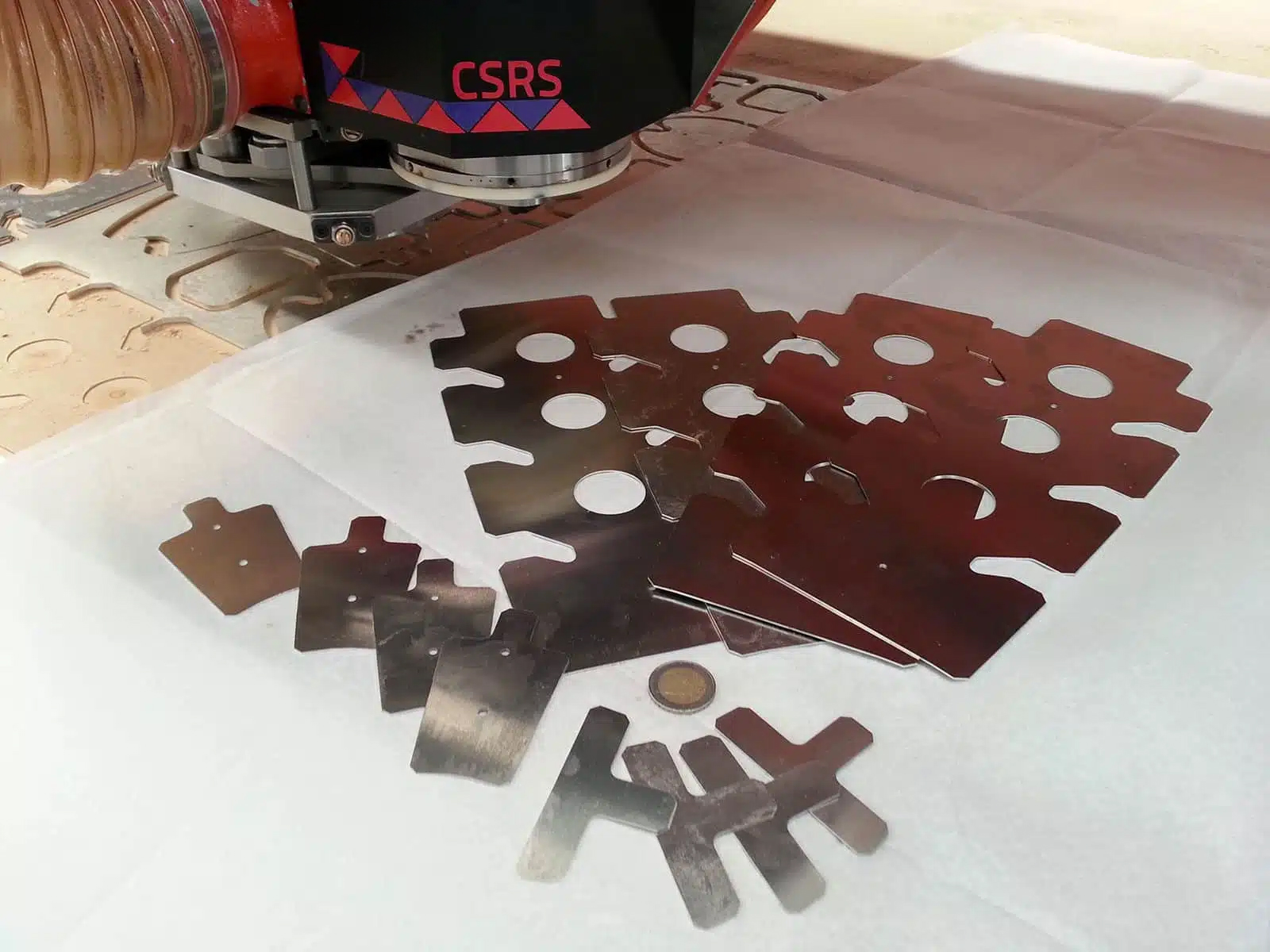

Machining operations are performed by a standard 3-axis machining center, typically of the NOVA Series. The head is equipped with CSRS (Caterpillar Stack Routing System), special equipment for a constant and high pressure compression on the tool zone during the whole operation.

This means stability of the sheet stack and the consequent improvement of finishing and operating speed, also solving the problem of the coolant penetration.

An efficient suction system keeps the working area clean, conveying the chips in a dedicated bin and simplifying final pieces unloading. In many cases Belotti S.p.A. solution allows to fringe completely the pieces, avoiding the usual tags: it is only necessary to stack precisely the sheets fixing them by four screws on the extremities on a plywood panel.

The standard 8 position tool change operates both with or without the locking system, removing the change time. The high power of the electrospindle, up to 30 kW, is motivated by the demand of strong removals in the production of aluminum mould.

Contact us for further technical information, sales requests or to schedule an on-line meeting.

Materials

- Light alloys

Contact us for product information, technical support or spare parts requests.