BES

Belotti Equipment Supervisor for the Industry 4.0

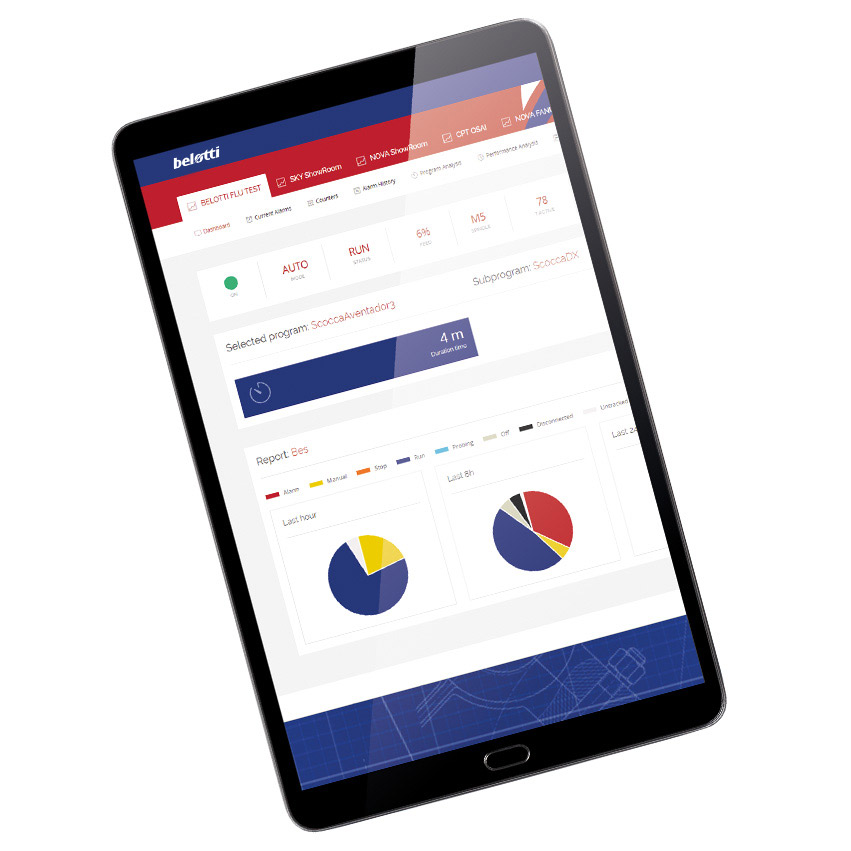

BES works as an Advanced Counter and Supervisor of machine productivity in ismart factories and Industry 4.0 environments (Performance Overall equipment effectiveness, OEE). The operational status of each CNC center logged-in the network is analysed on different time spans (shift, week, month).

Real-time monitoring and extraction of the relevant productivity data (SQL database and CSV report file) are simple and immediate as possible from several devices (PC, tablet, smartphone). Both the visualization and the extraction of the aggregate data of the machine is done in a simple and immediate way.

In addition to the Event Notification and Advanced Log services, BES allows to monitor and show into detail:

MACHINE STATUS:

(in operation, stop, cycle, switched off) through an easy-to-use dashboard;

RUNNING PROGRAM:

analysis and list of data on duration, number and type of executions, etc.;

PRODUCTIVITY:

through a special tachometer that measures the percentage of production capacity on different timings and regarding the number of machined pieces:

- daily percentage of machine work

- hourly percentage of machine work

- number of pieces produced.

We are available to provide further information and respond to your requests.

With the optional add-on OEM Variables, developed for BES and bOpen modules, it is possible to add up to 5 OEM variables to be monitored in particular, such as part numbers, batches, etc.

The performance of these variables are available real time, recorded and included in productivity reports.

The entire BES system is designed in order to easily integrate the aggregated data into the company’s management systems.

For more information about our products or a non-binding consultation fill out the form.