Waterjet

A technology with maximum versatility for fields of application and cutting geometries.

The flexibility of water cutting technology lends itself to the processing of multiple materials in all civil and industrial sectors. In addition to composite materials, Waterjet technology can be used for metal materials processing.

Description

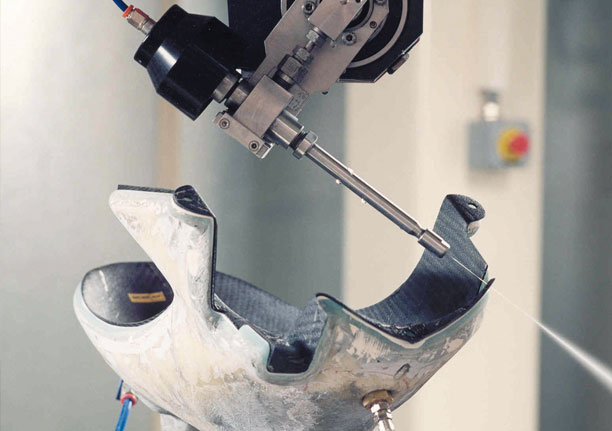

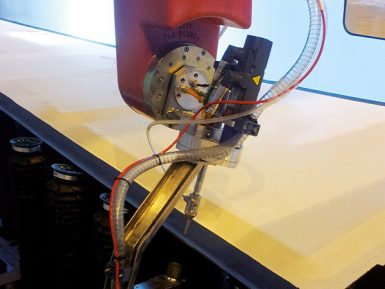

Waterjet technology by Belotti allows customers to work the most diverse materials with very high precision and speed, avoiding any deformations due to thermal and mechanical stress thanks to the “cold” cutting.

The low percentage of scraps and minimal tool wear make this technology very economical as well as low environmental impact.

The pressurized water flow at over 4,000 bar and is sent into an orifice with a diameter between 0.1 and 0.30 cm which transforms the pressure into a high-speed jet of pure water or with the addition of abrasive (to work also thicker and thicker materials).

The combination of Waterjet technology with milling is ideal for special processes, in which delamination of the material must be avoided and the quality of the cut must be guaranteed with an accuracy to the tenth of a millimeter.

Contact us for further technical information, sales requests or to schedule an on-line meeting.

Sectors

- Aerospace

- Automotive

- Railway

- Marine

- Design and furniture

- Medical

- Thermoformed

- Patterns and moulds

Materials

- Aluminium panels

- Composites

Contact us for product information, technical support or spare parts requests.