SKY Series

Series of 5-axis machining centers ideal for machining light alloy patterns and moulds and prototypes in composite or resin materials.

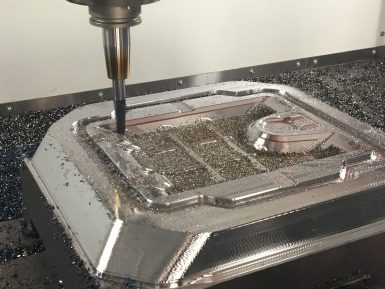

The Belotti SKY 5-axis CNC centres are particularly suitable for milling aluminium and light alloy patterns and moulds, milling resin prototypes for design centers, and trimming structural components in composite materials.

Description

Designed to mainly satisfy the specific applications of the automotive and aerospace industries, the Belotti SKY Series is the ideal solution for 5-axis multiple machining operations. Belotti SKY CNC machining centers feature a monolithic structure, thermally stabilized to ensure high machining precision and long-term stability, with axes movement managed by screw balls. The patented Belotti fork head, compact and sturdy, is equipped with torque motors and hydraulic locking brakes on the rotary axes, guaranteeing superior surface finish during simultaneous machining of linear axes interpolated with rotary axes A and C.

Total protection enclosures and vision cameras located in the spindle housing enable continuous verification of the work-cycle and unattended monitoring machining, while further raising the level of safety and operability.

Additional complementary options include the suction system with motorized hood, which is optimal for handling machining waste, and the liquid cooling system, equipped with filters and a chip conveyor, designed for high-volume aluminium processing. This system is also available in a special configuration for machining composite materials, and both contribute to maintain a cleaner and safer working environment.

Ultimately, the SKY Series can be integrated with advanced machining technologies such as ultrasonic cutting systems and 3D printing, which further expand the application potential of the machine tool in terms of types of machining and finishing of parts. These combinable technologies turn the SKY Series into an extremely versatile solution, suitable for a wide range of industrial applications.

Contact us for further technical information, sales requests or to schedule an on-line meeting.

Sectors

- Aerospace

- Automotive

- Railway

- Patterns and moulds

- Checking fixtures

Materials

- Light alloys

- Composites

- Resins

Technical features

| Axis | X | Y | Z | C | A |

|---|---|---|---|---|---|

| Stroke | 2,6/3,6 m | 1,7/2,2/3 m | 1,3 m | +/- 360° | +135° / -110° |

| Speed | 50 m/min | 30 m/min | 60 rpm | 60 rpm | |

| Spindle | From 22 kW up to 42 kW at 24.000 rpm max. | ||||

| CNC | Fanuc, Heidenhain, Siemens | ||||

| Tool change | From 18 to 200 positions | ||||

| Linear accuracy | ≤ 0,010 mm/m for linear axes | ||||

| Rotary accuracy | +/- 10 arcsec for rotary axes | ||||

| Measurement system | Linear scales, 5 micron resolution | ||||

| Combined technologies | Ultrasonic cutting system | Additive manufacturing | ||||

| Axis | X | Y | Z | C | A |

|---|---|---|---|---|---|

| Travels | 102/142″ | 67/86/118″ | 51″ | +/- 360° | +135° / -110° |

| Rapids | 1,270 ipm | 762 ipm | 60 rpm | 60 rpm | |

| Spindle | From 30 HP up to 68 HP at 24,000 rpm max. | ||||

| CNC | Fanuc, Heidenhain, Siemens | ||||

| Tool change | From 18 to 200 positions | ||||

| Linear accuracy | ≤ 0,004″ / 40″ for linear axes | ||||

| Rotary accuracy | +/- 10 arcsec for rotary axes | ||||

| Measurement system | Linear scales, 5 microns (0,0002″) resolution | ||||

| Combined technologies | Ultrasonic cutting system | Additive manufacturing | ||||

Accessories

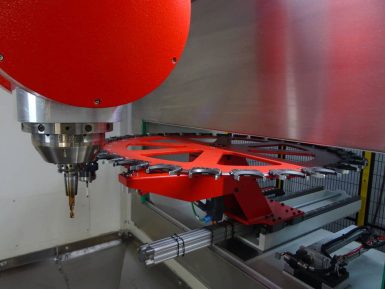

Fork head

The patented Belotti 5-axis fork head with cast iron structure ensures exceptional precision during the machining process and is also equipped with hydraulic brakes on the A and C axes.

The C axis is managed by a torque motor, while the A axis is activated by a torque multiplier and backlash recovery motor.

Particularly suitable for achieving a higher degree of surface finish during simultaneous machining of linear axes interpolated with the A and C rotary axes, the head with the center of rotation of the A-axis spindle offset can achieve an undercut of 45°, allowing the lower machining of the workpiece.

Due to its symmetry, it provides better stability and rigidity and is particularly suitable for aluminium machining in the automotive, aerospace, and mechanical industries.

Dust suction grids with air ducting and requalification

The machining center is equipped with dust suction grids located at the front of the machine or on the rear panel, allowing good dust extraction during milling operations.

Suction hood

High-pressure suction system for 5-axis head with electronic control, suitable for dust and chips removal in the working environment. The extension of the motorized electronic hood automatically adjusts according to the tool length and the workpiece machining depth.

Total enclosure with moving roof - SKY

The complete/total enclosure, made with sound-absorbing panels, is designed to ensure the machine compliance to the European noise regulations for machining centers.

The automatic upper doors feature an opening suitable for overhead crane insertion of machining components, while the manual lower doors have a wide opening allowing them to be loaded in conjunction with machine strokes.

Upper rolling shutter

The motorized rolling shutter limits chip ejection from the work environment, facilitating opening/closing operations and workpiece loading via overhead crane.

The artificially lit work environment is also well-visible thanks to the special translucent fabric of the shutter.

Cooling liquid system with chip conveyor

Contact us for product information, technical support or spare parts requests.