FLA Series

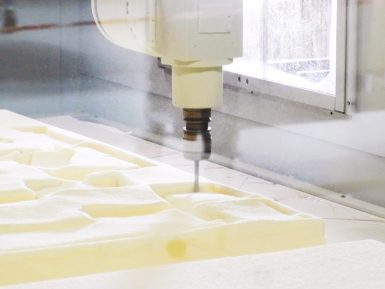

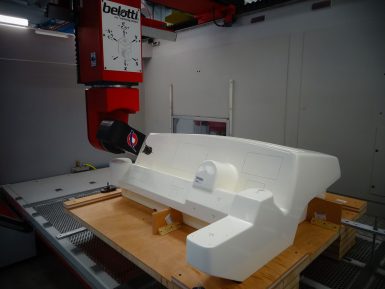

High-speed 5-axis machining centers for high-volume trimming of composite and thermoplastic components and for milling resin or light alloys models.

The Belotti FLA Series represents the best mix of high machining speed and rigidity of the mobile bridge system.

The excellent dynamism of the axes and the customizable operating units with electrospindle up to 22 kW or multispindle (revolver or double exit spindle) – guarantee production efficiency for specific applications in many industrial sectors: automotive, aerospace, railway, marine, thermoforming, patterns and moulds processing.

Description

Belotti FLA 5-axes CNC machining centers combine the productivity of a high-speed milling machine and the potential of a mobile bridge machining center in a single solution.

These centers are particularly recommended for the mass production trimming of components in composite (such as carbon fiber, glass fiber and Kevlar) and thermoplastics materials and for the milling of resin and light alloys products. The FLA Series structure, with baseframe or columns, is optimized for the machining of these materials, thus ensuring stability and accuracy throughout the entire life cycle of the machine.

For greater productivity, the FLA machining centers can be configured with automated loading and unloading systems, as rotary tables, “Single Shuttle” or “Twin Shuttle” loaders, for a quick tooling of the 5-axis milling machine.

The model with rotary table allows to almost zero the set-up times of the equipment, simplifying and speeding up the loading/unloading operations of the workpieces, while the model with “Twin Shuttle” allows to maximize the use of the machining center.

The tool changer, with modular design and automatic change, can be customized with configurations from 8 to 60 positions.

Belotti FLA machining centers can be integrated with advanced technologies such as ultrasonic cutting systems, waterjet cutting and 3D printing extruders.

The FLA Series is designed with consideration for workplace cleanliness and safety, ensured through effective extraction systems and protective cabins that significantly reduce dust emissions and noise levels.

Contact us for further technical information, sales requests or to schedule an on-line meeting.

Sectors

- Automotive

- Railway

- Aerospace

- Marine

- Thermoformed

- Patterns and moulds

- Design and furniture

- Medical

- Energy and building

Materials

- Composites

- Plastic

- Resins

- Technical plastic

- Light alloys

Technical features

| Axis | X | Y | Z | C | A |

|---|---|---|---|---|---|

| Stroke | 3/4/5/5,5/6,5/9/12 m | 1,8/2,6/3,2 m | 0,9/1,3/2 m | +/- 270° | +/- 120° |

| Speed | 80 m/min | 60 m/min | 44 rpm | 40 rpm | |

| Spindle | From 6,5 kW up to 22 kW at 24.000 rpm max. | ||||

| CNC | Heidenhain, Osai, Siemens | ||||

| Tool change | From 8 to 60 positions | ||||

| Linear accuracy | ≤ 0,03 mm/m for linear axes | ||||

| Rotary accuracy | +/- 24 arcsec for rotary axes | ||||

| Measurement system | Linear scales, 5 microns resolution | ||||

| Combined technologies | Waterjet | Ultrasonic cutting system | Additive manufacturing | ||||

| Axis | X | Y | Z | C | A |

|---|---|---|---|---|---|

| Travels | 118/157/197/216/256/354/433″ | 71/102/126″ | 35/51/79″ | +/- 270° | +/- 120° |

| Rapids | 2,032 ipm | 1,524 ipm | 44 rpm | 40 rpm | |

| Spindle | From 9 HP up to 30 HP at 24,000 rpm max. | ||||

| CNC | Heidenhain, Osai, Siemens | ||||

| Tool change | From 8 to 60 positions | ||||

| Linear accuracy | ≤ 0,0012″ / 40″ for linear axes | ||||

| Rotary accuracy | +/- 24 arcsec for rotary axes | ||||

| Measurement system | Linear scales, 5 microns (0,0002″) resolution | ||||

| Combined technologies | Waterjet | Ultrasonic cutting system | Additive manufacturing | ||||

Accessories

Linear scales

Direct incremental measuring system for all linear axes with pressurized, metal graduated scale.

Two models available:

- single section unit with glass optical scale for lengths up to 4 m.

- multi-section unit with steel optical scale for lengths from 4 m to 72 m. In comparison with the steel band version, this model is not affected by temperature variations.

Single or Twin Shuttle loading/unloading system

This system separates the loading/unloading area from the machining area, providing great advantages to the user.

The “Single Shuttle” model has a platform which is twice as long as the working area (but its width remains fixed). This table slides on linear re-circulating ball ways and is managed by gear motors. Loading and unloading operations take place alternatively on the two opposite sides of the machine and the functions of the loading device are managed by CNC.

When equipped with the “Twin Shuttle” system the two tables, positioned in front of the machine, can be used independently, in case of dual zone functionality (one table working, the other one loading) or coupled, when required by the dimension of the part.

The transparent automatic door, moving vertically, shifts according to the platform movements. Each table is accessible on at least two sides, to make part loading/offloading easier.

Rotary table

The ideal solution when it is necessary to insulate the working area because of loud noise and dust. It consists of two tables with a screen between them which is sealed with the enclosure.

While the operator is loading/unloading on one table, the other one is in operation: this alternate cycle allows a considerable increase of productivity avoiding the waste of time during loading/unloading procedures.

Dust extraction grids + suction hood + total enclosure

The machining center is equipped with dust suction grids that can be connected to an extraction system via rear manifolds.

The suction hood, with electronic or pneumatic control, removes dust during 5-axis machining, while the total enclosure, made of steel to fit sound-absorbing panels, ensures compliance with regulations regarding noise and a clean and safe working environment.

Cooling liquid system with waste collection tanks

Cooling liquid system with chip conveyor and liquid collection tank, equipped with mechanical paper filer system and low/high pressure pumps and liquid coolant chiller.

Double bridge

Independent second bridge equipped with the same cutting head as the first bridge or with different heads. The ideal solution to increase machine productivity and flexibility.

Automatic tool changer up to 60 positions

The 18/60-position carrousel type tool changer is installed in a suitable rear opening of the machine easily reachable from the outside for the tool change without interrupting the machining operations.

Electronic suction hood

Dust suction hood for 5-axis milling, electronically controlled.

In a range of 100 mm the electronic hood allows to automatically adapt its extension depending on the real work piece distance.

Extraction unit

Contact us for product information, technical support or spare parts requests.