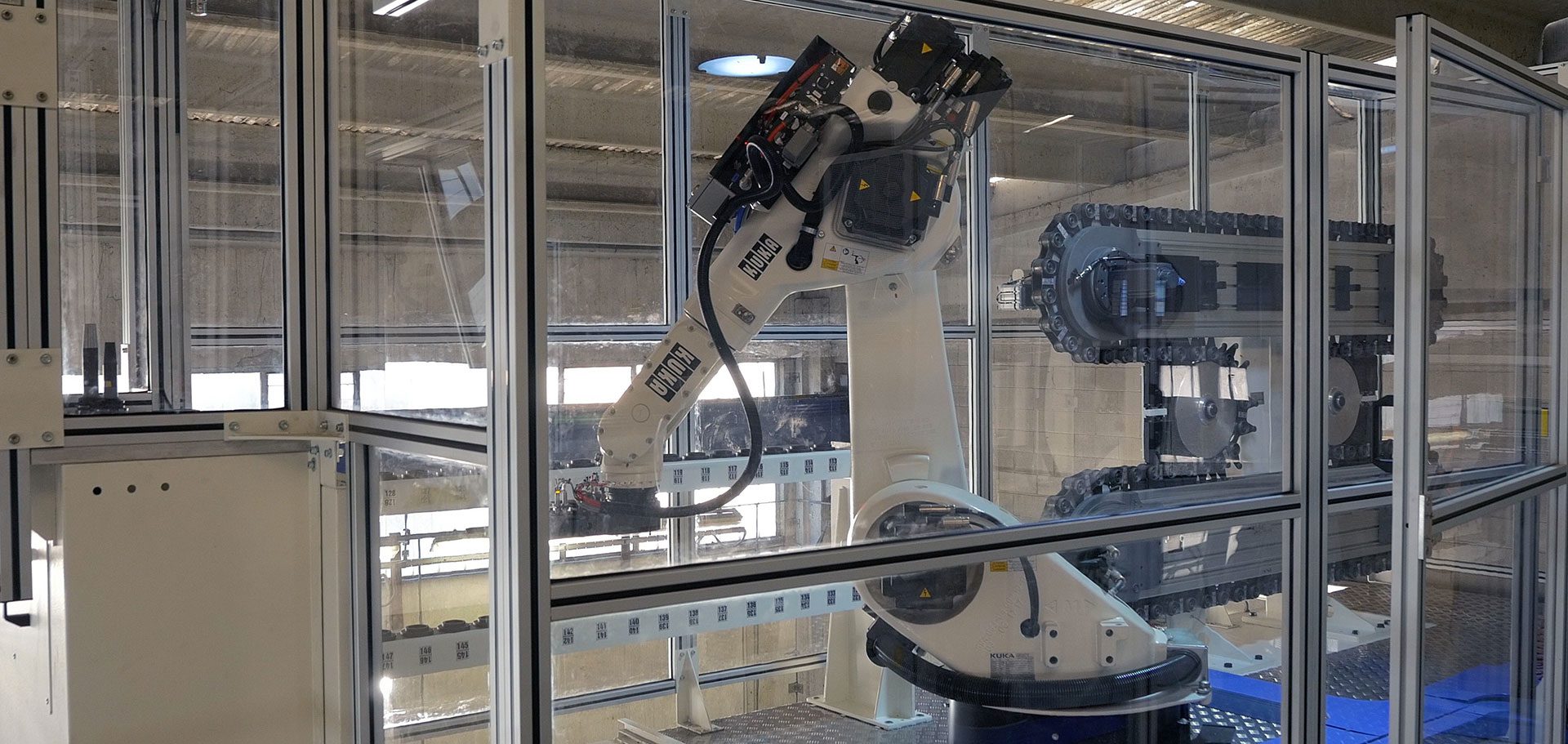

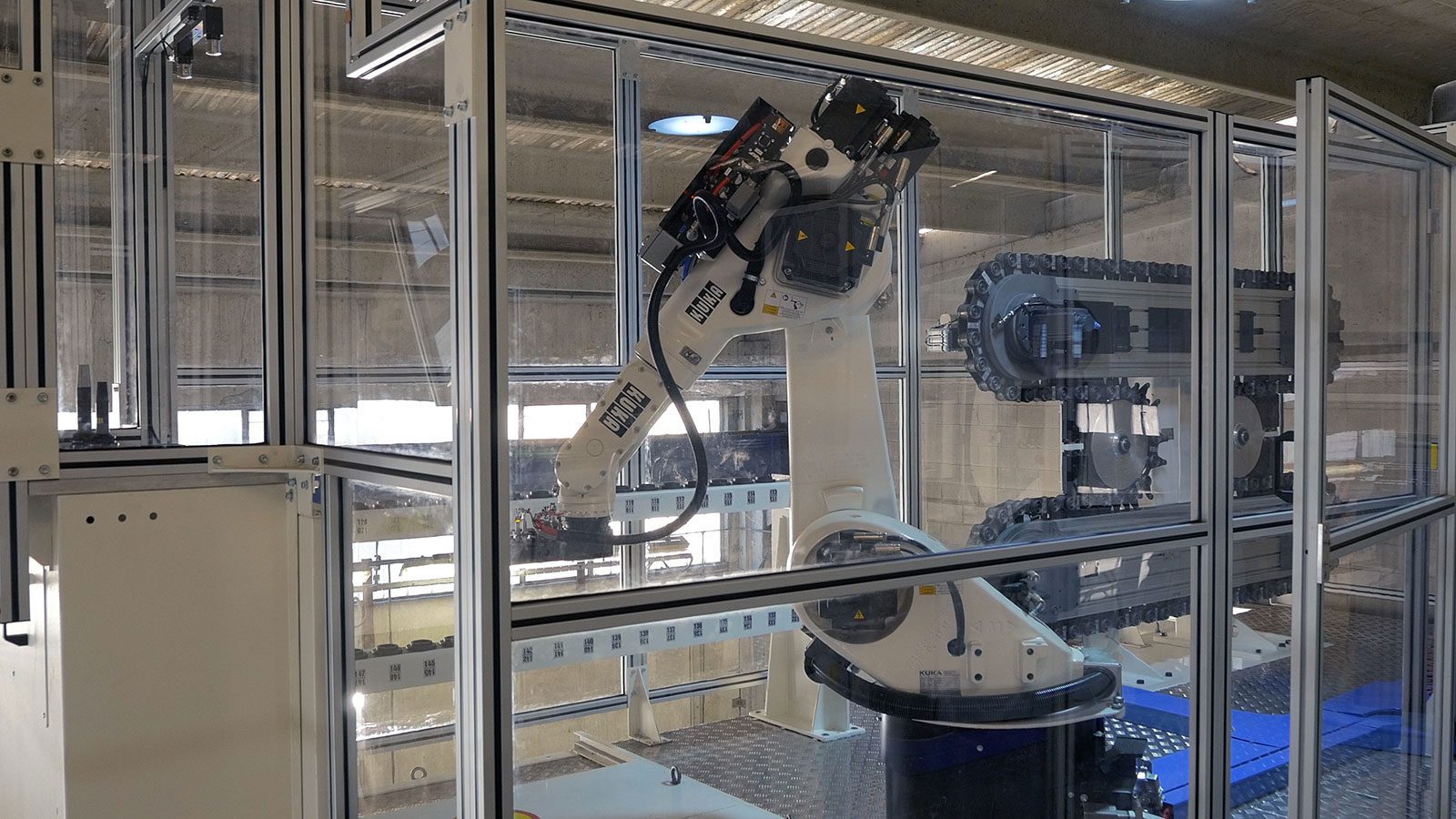

Belotti Robotic Automation is the business unit that operates to simplify the production processes of companies and to increase their productivity by providing “turnkey” automated solutions.

Choosing to entrust Belotti for the implementation of automation processes means benefitting from the strategic and operational advantage of having one unique partner during all phases (design, production, implementation, and maintenance of the solution).

Belotti guarantees competence and timeliness of intervention both on the single CNC machining center and on the automation technologies that feed it upstream and / or downstream of processing.

Since the development of the first pilot solutions for important customers in various application sectors (such as the first Belotti Integrale modular cell made for the assembly line of Automobili Lamborghini’s Super SUV Urus), we have continued to invest in research and innovation to enhance this business unit and offer solutions that meet specific logistical and production needs.

From the analysis of the customer’s context and objectives to the design of more or less complex automation lines or cells, even with the integration of anthropomorphic robots, the Belotti Automation team works to offer customers significant competitive advantages:

1. Return on investment in the short term;

2. Cost reduction: releasing the company from fluctuations in the availability of skilled labor and providing a single qualified partner ensure economic savings by avoiding waste of resources;

3. Increased productivity: employees can devote more time to activities with greater added value for the company, letting the automation take care of repetitive actions;

4. High reliability: limiting manual processes means reducing the risk of error and increasing reliability by being able to establish with certainty when processes, tests, updates and workflows will take place, how long they will last and how reliable the results will be;

5. Greater safety: industrial automation can make the production line safe for employees by using robots to manage dangerous activities;

6. Spaces optimization: inserting automated cells or lines within the production leads to a more logical and functional way of using factory areas.

Contact us for further technical information, sales requests or to schedule an on-line meeting.