12 March 2024

We proudly unveil BEAD machine integration into ADAXIS’s AdaOne software, a groundbreaking advancement in additive manufacturing for tooling and moulds.

This collaboration with ADAXIS is a significant milestone in manufacturing excellence, offering a simple tool that democratizes the fabrication of complex large-scale parts.

Multi-axis additive manufacturing, combined with cnc machining, has emerged as a compelling alternative amidst the evolving challenges of manufacturing industries. Making Belotti BEAD technology accessible and cost-effective has been a clear objective for us from the outset: initially through collaboration with CEAD, which brought BEAD to market, and now collaborating with ADAXIS to deliver a turnkey user experience.

The additive process excels in tooling and draping mould production, reducing lead times, increasing production flexibility, and ensuring cost and inventory control. However, its effective utilization requires significant expertise and methodology.

This collaboration prioritizes user experience by offering simple, robust, and accessible workflows, allowing operators of any level to easily program and oversee mould printing from a simple CAD file. AdaOne software is an ultimate platform that makes possible to program and control robotic arms as large scale 3D printers for a wide array of materials.

“The collaboration with ADAXIS enables us to offer our customers an integrated turnkey solution, comprising seamlessly integrated equipment and software, making our technology and expertise instantly accessible to a broader audience”, says Alberto Riganti, Belotti Additive Manufacturing Specialist.

Innovative Features in AdaOne

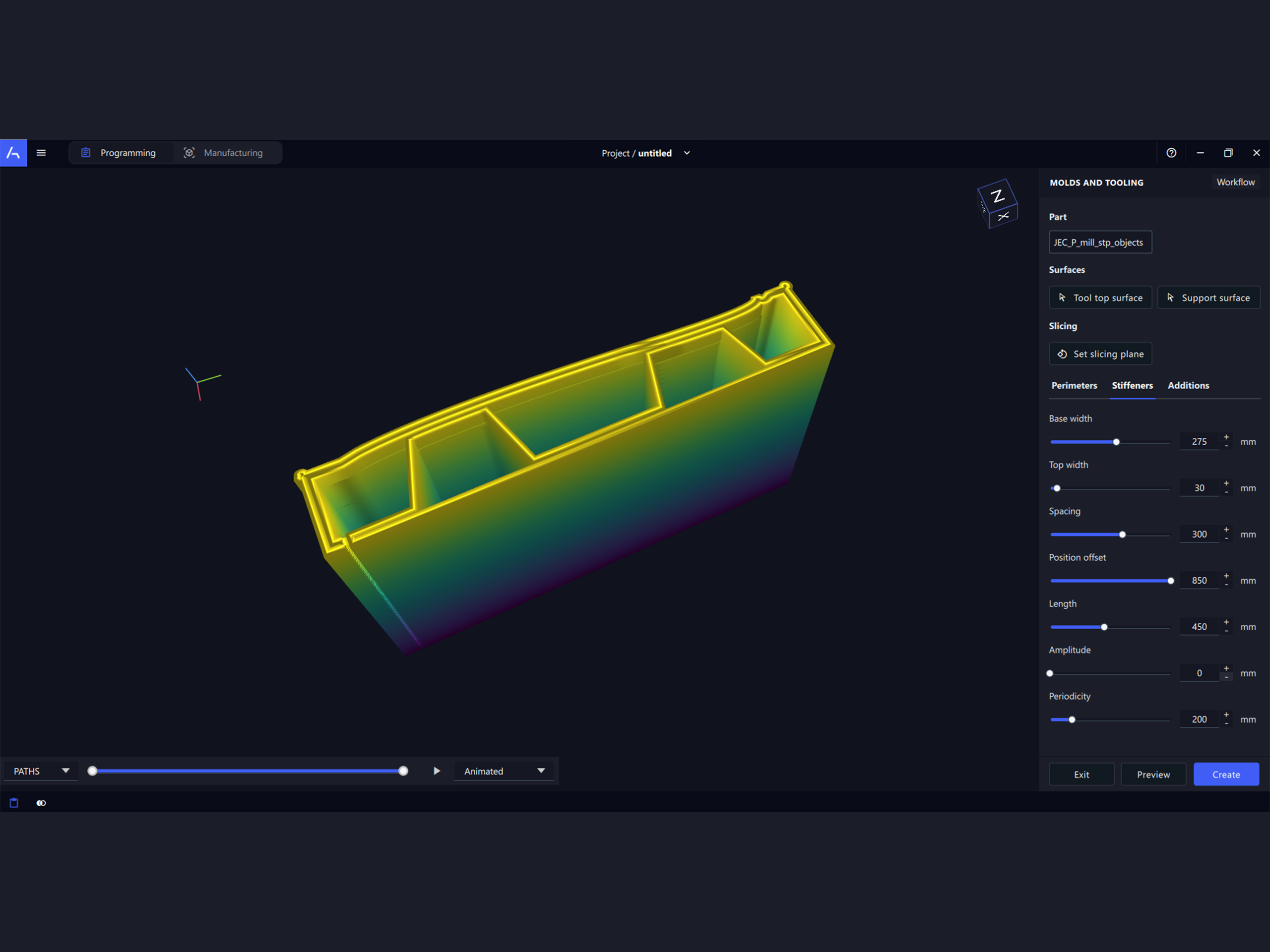

AdaOne introduces a range of unique features tailored for tooling production:

- Automatic Internal Support: reduces design time and material usage by automatic generation of internal stiffeners inside the tooling geometry.

- Localized Double Bead on Main Surfaces: generation of machining margin and local reinforcement to facilitate machining of the tooling surfaces.

- Selective corner compensation: adds extra material at corners to ensure correct final geometry after machining.

- Continuous printing path: minimize starts and stops through automatic seam positioning and tool path optimization.

AdaOne also generates machining trajectories, providing operators with a comprehensive turnkey solution.

Optimization and Efficiency at the core

The AdaOne integration with the BEAD technology, backed by Belotti’s expertise, isn’t just technically compatible; it simplifies path programming and reduces both material usage and print time. In addition, a collaboration with Airtech ensures that operators get pre-configured settings tailored to their materials, meeting industry standards seamlessly.

“Collaborating with Belotti’s expert team while applying our expertise in user experience and software development allows us to integrate numerous and unique features into a robust, stable, and industrial-grade solution,” says Emil Johansson, CPO of ADAXIS.

The strategic collaboration was made official at JEC World 2024 expo in Paris (March, 5-7). More details about AdaOne software features for Belotti BEAD machine are displayed in “Belotti BEAD machine integration into ADAXIS AdaOne software for mould workflow” video.