VEGA Series

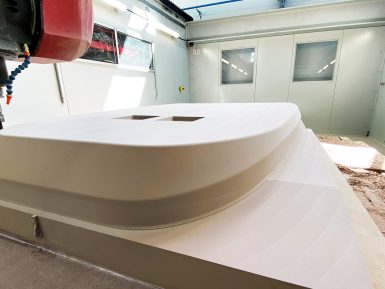

High-speed gantry machining centers for machining large components in composite materials and resin prototypes.

The VEGA Series offers high-speed gantry machining centers that are ideal for ensuring the highest accuracy in the production of resin models and prototypes for style centers and large components in composite materials.

Description

The high-speed CNC gantry machining centers of the VEGA Series are the result of Belotti’s extensive experience in the production of 5-axis technologies for carbon and aluminium milling, designed to meet the production needs of the automotive, aeronautical, and marine sectors, and more generally of the major modelers and manufacturers of composite components (carbon, Kevlar, fiberglass, honeycomb).

The VEGA Series models have a dynamically rigid structure that is ideal for offering a unique combination of performance: short processing times, flexibility, high quality surface finish, and rigidity over time. Total enclosure, dust extraction grids, push and pull systems, and vision cameras ensure a safer working environment for operators.

Contact us for further technical information, sales requests or to schedule an on-line meeting.

Sectors

- Aerospace

- Automotive

- Patterns and moulds

- Railway

Materials

- Composites

- Resins

- Light alloys

Technical features

| Axis | X | Y | Z | C | A |

|---|---|---|---|---|---|

| Stroke | 2,6/6/8/12/17/20/23/30/43 m | 3,2/4,2/6,2/7,2/8,8 m | 1,5/2/3/3,3/4,2/5,3/6,9 m | +/- 270° | +/- 120° |

| Speed | 100 m/min | 45 m/min | 44 rpm | 40 rpm | |

| Spindle | From 15 kW up to 42 kW at 24.000 rpm max. | ||||

| CNC | Fanuc, Heidenhain, Siemens | ||||

| Tool change | From 18 to 60 positions | ||||

| Linear accuracy | ≤ 0,015 mm/m for linear axes | ||||

| Rotary accuracy | +/- 15 arcsec for rotary axes | ||||

| Measurement system | Linear scales, 5 micron resolution | ||||

| Combined technologies | Ultrasonic cutting system | Additive manufacturing | ||||

| Axis | X | Y | Z | C | A |

|---|---|---|---|---|---|

| Travels | 8.5/19.7/26/39/56/65.6/75/98/141 ft | 10.5/14/17/20/23.6/29 ft | 5/6.5/9.8/10.8/13.8/17/22.6 ft | +/- 270° | +/- 120° |

| Rapids | 2,540 ipm | 1,143 ipm | 44 rpm | 40 rpm | |

| Spindle | From 20 HP up to 57 HP at 24,000 rpm max. | ||||

| CNC | Fanuc, Heidenhain, Siemens | ||||

| Tool change | From 18 to 60 positions | ||||

| Linear accuracy | ≤ 0,0006″ / 40″ for linear axes | ||||

| Rotary accuracy | +/- 15 arcsec for rotary axes | ||||

| Measurement system | Linear scales, 5 micron (0,0002″) resolution | ||||

| Combined technologies | Ultrasonic cutting system | Additive manufacturing | ||||

Accessories

5-axis single-shoulder head up to 42 kW

Single-shoulder head enabling three-dimensional tilting and orientation of the tool. Equipped with servo motors with gearboxes and a direct measuring system, it ensures dynamic and precise machining. The head is equipped with a rotary axis clamping system that enables greater machining rigidity.

Dust suction grids + suction hood

VEGA machining center is equipped with dust extraction grids positioned under the two runways, or on the side panels of the machine, allowing the dust extraction during milling operations.

The 5-axis head is equipped with a high-pressure suction system and an electronic control for the removal of dust and chips in the working area. The extension of the electronic hood can be managed by the software and it adapts automatically according to the length of the tool and the piece’s machining depth.

Total enclosure with moving roof - VEGA

The total enclosure, made of sound-absorbing panels, is designed to guarantee compliance to the current European noise rules for machining centers.

The automatic upper doors have a suitable opening for loading of parts through bridge crane.

Manual lower doors have a wide opening to enable loading of pieces according to the machine strokes.

Upper rolling shutter

The motorized rolling shutter limits chip ejection from the work environment, facilitating opening/closing operations and workpiece loading via overhead crane.

The artificially lit work environment is also well-visible thanks to the special translucent fabric of the shutter.

Double bridge

Independent second bridge equipped with the same cutting head as the first bridge or with different heads. The ideal solution to increase machine productivity and flexibility.

Vision cameras

Vision cameras in the spindle housing for work cycle verification and monitoring during unattended machining.

Push and pull system

Suction system of different flow rates depending on the volume of the machine, characterized by suction inlets on one side of the enclosure and filtered air reintegration inlets on the opposite side.

This system, which is particularly suitable for very dusty environments, ensures greater cleanliness and safety due to more effective extraction of dust generated by processing and the flow of air created inside the booth.

Contact us for product information, technical support or spare parts requests.