MDL Series

Advanced high-speed machining centers particularly suitable for the automotive and aerospace sectors.

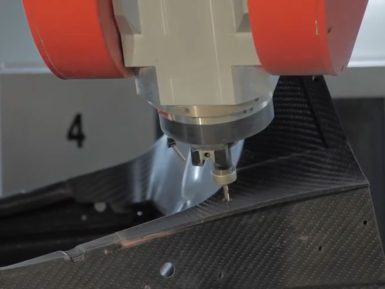

The MDL Series 5-axis CNC centers are used with great versatility for milling light alloy patterns and moulds and for trimming large structural components in composite materials.

Description

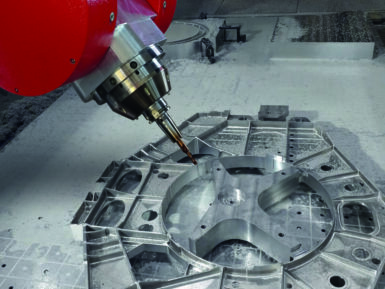

The Belotti MDL Series offers advanced high-speed 5-axis CNC machining centers hat ensure maximum productivity in milling patterns and prototypes and finishing processes of large moulds and aluminium/composite parts for the aerospace sector.

The adoption of 5-axis heads equipped with torque motors, linear scales on the linear axes, and very high rigidity structures enhance the accuracy features and quality of finishes.

A wide range of models and operating units enables all dimensional and technological requirements to be met.

Options available to ensure optimal clean and safe working environment conditions include:

- Total safety enclosures, equipped with advanced filtration systems, designed for complete dust suppression and reduction of machine noise. In their moving roof version, they allow part loading via overhead crane.

- Vision cameras in the spindle housing for checking the work cycle and monitoring unattended machining, a feature that ensures both a higher level of safety and the ability to take prompt action in case of anomalies during the production process.

- Suction system with motorized hood, that significantly improves cleaning conditions in the work environment, ensuring efficient removal of machining residues.

- Cooling liquid system with chip conveyor, beneficial for maintaining a clean and safe working environment, reducing downtime and increasing operational efficiency.

The MDL Series 5-axis machining centers are compatible with a variety of advanced technologies, including abrasive waterjet for especially hard materials, ultrasonic cutting system for delicate materials requiring high precision processing, and 3D printing for rapid prototyping and patterns and moulds manufacturing.

Contact us for further technical information, sales requests or to schedule an on-line meeting.

Sectors

- Aerospace

- Automotive

- Railway

- Patterns and moulds

Materials

- Light alloys

- Composites

- Resins

Technical features

| Axis | X | Y | Z | C | A |

|---|---|---|---|---|---|

| Stroke | 4/6/8/12/16/23/30 m | 2,6/3/3,6/4/4,8/6,5 m | 1,3/1,5/2/2,5/3/4,5 m | +/- 360° | + 135° / -110° |

| Speed | 50 m/min | 30 m/min | 60 rpm | 60 rpm | |

| Spindle | From 30 kW up to 50 kW at 24.000 rpm max. | ||||

| CNC | Fanuc, Heidenhain, Siemens | ||||

| Tool change | From 18 to 200 positions | ||||

| Linear accuracy | ≤ 0,010 mm/m for linear axes | ||||

| Rotary accuracy | +/- 10 arcsec for rotary axes | ||||

| Measurement system | Linear scales, 5 microns resolution | ||||

| Combined technologies | Abrasive waterjet | Ultrasonic cutting system | Additive manufacturing | ||||

| Axis | X | Y | Z | C | A |

|---|---|---|---|---|---|

| Travels | 157/236/315/472/630/905/1181 ″ | 102/118/142/157/189/256″ | 51/59/79/98/118/177″ | +/- 360° | + 135° / -110° |

| Rapids | 1,270 ipm | 762 ipm | 60 rpm | 60 rpm | |

| Spindle | From 30 HP up to 68 HP at 24,000 rpm max. | ||||

| CNC | Fanuc, Heidenhain, Siemens | ||||

| Tool change | From 18 to 200 positions | ||||

| Linear accuracy | ≤ 0,0004″ / 40″ for linear axes | ||||

| Rotary accuracy | +/- 10 arcsec for rotary axes | ||||

| Measurement system | Linear scales, 5 microns (0,0002″) resolution | ||||

| Combined technologies | Abrasive waterjet | Ultrasonic cutting system | Additive manufacturing | ||||

Accessories

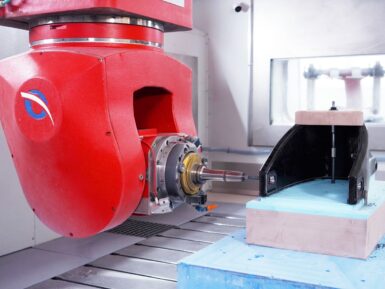

Fork head up to 50kW

5-axis working head with Belotti patent for maximum high precision during machining. This model is equipped with electrospindle with power up to 50kW allowing tool tilting and orientation in all directions. It is equipped with a scale inductive type measurement system to ensure high dynamic performance and accuracy.

Furthermore, the head is equipped with a hydraulic rotary axis clamping system, enabling greater machining rigidity when interpolation is not required.

Total enclosure with moving roof

The total enclosure, made with sound-absorbing panels, is designed to ensure the machine compliance to the European noise regulations for machining centers.

The automatic upper doors feature an opening suitable for overhead crane insertion of machining components, while the manual lower doors have a wide opening allowing them to be loaded in conjunction with machine strokes.

Upper rolling shutter

The motorized rolling shutter limits chip ejection from the work environment, facilitating opening/closing operations and workpiece loading via overhead crane.

The artificially lit work environment is also well-visible thanks to the special translucent fabric of the shutter.

Cooling liquid system with chip conveyor

Cooling liquid system equipped with a chip conveyor, a liquid collection tank with mechanical fabric filter purifier, and high- and low-pressure pumps.

Double bridge

Independent second bridge equipped with the same cutting head as the first bridge or with different heads. The ideal solution to increase machine productivity and flexibility.

Vision cameras

Contact us for product information, technical support or spare parts requests.