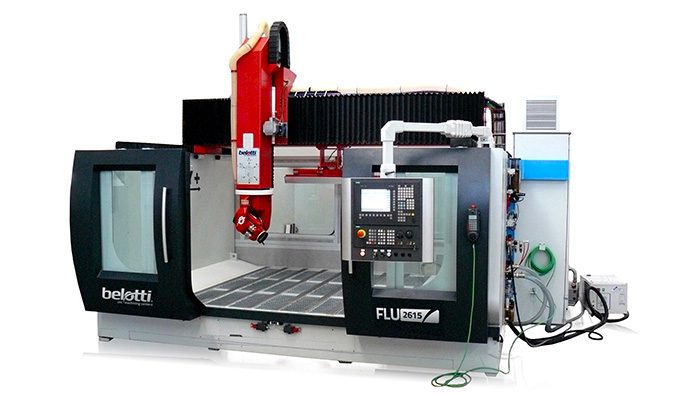

FLU Series

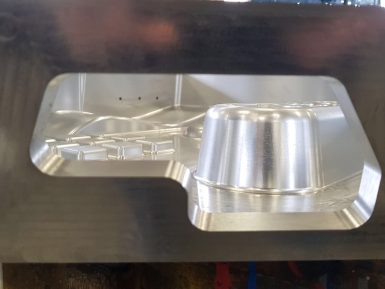

5-axis machining centers for high-speed milling of resin and aluminium patterns and moulds and trimming of composite materials.

The Belotti FLU 5-axis CNC centers, featuring a robust structure meticulously crafted to absorb vibrations, represent the optimal solution for high-speed milling of resin patterns and aluminium moulds.

Description

Thanks to the welded and heat-treated steel structure, available in single- or double-shoulder versions (the latter particularly suitable for high production volumes), Belotti FLU machining centers ensure high rigidity and total stability of the machine.

This Series high-speed processing enables a significant reduction in cycle times, while the use of High Performance HP or High Performance 2 models of single-shoulder machining units provides a significant improvement in milling precision and the achievement of top-quality finishes.

The unique architecture of the FLU Series guarantees total accessibility to the work environment, offering the possibility of loading both jigs and particularly heavy workpieces using a forklift or overhead crane.

Furthermore, FLU machining centers can be tailored to clients’ specific production needs, choosing from a wide range of tables, safety enclosures, and advanced accessories including extruders for additive manufacturing (3D printing) and ultrasonic cutting systems.

Contact us for further technical information, sales requests or to schedule an on-line meeting.

Sectors

- Automotive

- Patterns and moulds

- Medical

- Design and furniture

- Checking fixtures

- Packaging

- Aerospace

Materials

- Resins

- Composites

- Light alloys

- Technical plastic

- Plastic

Technical features

| Axis | X | Y | Z | C | A |

|---|---|---|---|---|---|

| Stroke | 2,6/4 m | 1,7/1,8/3,2 m | 1/1,3 m | +/- 270° | +/- 120° |

| Speed | 80 m/min | 60 m/min | 44 rpm | 40 rpm | |

| Spindle | From 15 kW up to 22 kW at 24.000 rpm max. | ||||

| CNC | Fanuc, Heidenhain, Siemens | ||||

| Tool change | From 8 to 60 positions, also with exchange arm | ||||

| Linear accuracy | ≤ 0,02 mm/m for linear axes | ||||

| Rotary accuracy | +/- 12 arcsec for rotary axes | ||||

| Measurement system | Linear scales, 5 microns resolution | ||||

| Combined technologies | Ultrasonic cutting system | Additive manufacturing | ||||

| Axis | X | Y | Z | C | A |

|---|---|---|---|---|---|

| Travels | 102/157″ | 67/71/126″ | 39/51″ | +/- 270° | +/- 120° |

| Rapids | 2,032 ipm | 1,524 ipm | 44 rpm | 40 rpm | |

| Spindle | From 20 HP up to 30 HP at 24,000 rpm max. | ||||

| CNC | Fanuc, Heidenhain, Siemens | ||||

| Tool change | From 8 to 60 positions, also with exchange arm | ||||

| Linear accuracy | ≤ 0,0012″ / 40″ for linear axes | ||||

| Rotary accuracy | +/- 12 arcsec for rotary axes | ||||

| Measurement system | Linear scales, 5 microns (0,0002″) resolution | ||||

| Combined technologies | Ultrasonic cutting system | Additive manufacturing | ||||

Accessories

Linear scales

Direct incremental measuring system for all linear axes with pressurized, metal graduated scale.

Two models available:

- single section unit with glass optical scale for lengths up to 4 m.

- multi-section unit with steel optical scale for lengths from 4 m to 72 m. In comparison with the steel band version, this model is not affected by temperature variations.

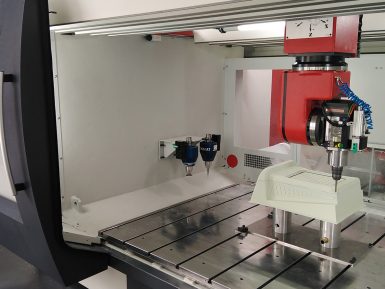

HP2 head

Single-shoulder machining unit engineered by Belotti: precise, reliable, with a minimalist and compact design.

The special monolithic cast iron structure ensures high standards of rigidity and temperature stability, while minimizing vibrations during the machining process.

The High Performance 2 head incorporates bearings reinforcing the head and C-axis to both reduce vibration and increase the rigidity of the head itself.

Dust suction grids

The machining center is equipped with two dust suction grids machined from the rear panel at work-table height, which can be connected to an extraction system via rear manifolds.

Total enclosure with moving roof - FLU

The total enclosure, made with sound-absorbing panels, is designed to ensure the machine compliance to the European noise regulations for machining centers.

The automatic upper doors feature an opening suitable for overhead crane insertion of machining components, while the manual lower doors have a wide opening allowing them to be loaded in conjunction with machine strokes.

Upper rolling shutter

The motorized rolling shutter limits chip ejection from the work environment, facilitating opening/closing operations and workpiece loading via overhead crane.

The artificially lit work environment is also well-visible thanks to the special translucent fabric of the shutter.

Cooling liquid system with chip conveyor

Contact us for product information, technical support or spare parts requests.