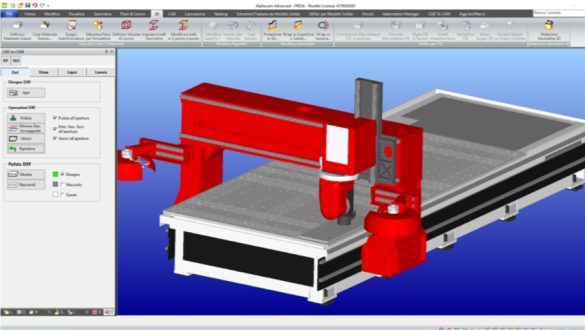

GEMINI Series

3-axis machining centers for the processing of plastic and composite panels.

GEMINI is the most efficient Series for the processing of plastic and composite materials in dual-zone functionality, eliminating downtime.

Description

Belotti GEMINI machining centers ensure extreme efficiency, which translates into optimization of production times and maximum finishing quality, thanks to the rigidity of the fixed bridge and moving tables’ structure and the durability of materials over time (reinforced and sturdy cast iron and stress-relief welded steel).

The longitudinal movement X, with rack and pinion system, is obtained with the displacement from right to left of the wagon Z, where it accommodates the ball screw that moves the vertical axis (Z axis). The transverse movements (Y and V axes) – obtained with ball screws – manage the work tables, independent of each other, with high precision handling systems.

Contact us for further technical information, sales requests or to schedule an on-line meeting.

Sectors

- Marine

- Energy and building

- Packaging

Materials

- Composites

- Plastic

- Technical plastic

- Resins

Technical features

| Axis | X | Y | Z | C | A |

|---|---|---|---|---|---|

| Stroke | custom | custom | custom | +/- 270° | +/-120° |

| Speed | 60 m/min | 40 m/min | 30 m/min | 44 rpm | 40 rpm |

| Spindle | From 15 kW to 22 kW at 24.000 rpm max. | ||||

| CNC | Siemens, Osai | ||||

| Tool Change | From 12 to 60 positions | ||||

| Linear axes | ≤ 0,03 mm/m for linear axes | ||||

| Rotary axes | +/- 15 arcsec for rotary axes | ||||

Accessories

5-axis high performance head up to 22 kW

5-axis head with electrospindle, direct drive encoders and rotary axis pneumatic locking system. It can be used as a replacement for the 3-axis version or installed as a second independent 5-axis head (dual head solution).

Multihead with variable center distance

Front head combined with rear head + loading/unloading system

Aluminium vacuum table with MDF panel

Aluminium table on which MDF panels are screwed, especially designed for machining of aluminium plates.

The table is divided into 12 areas, with dimensions to be defined, that can be automatically managed by the CNC. It is equipped with vacuum electrovalves and preset vacuometers to check the minimum vacuum level on the part for safe clamping.

In case mechanical clamping is needed, the MDF panel can be removed.

Upon request, it will be possible to provide multiple rapid connections for vacuum clamping.

Multiblade saw with 0-90° automatic positioning

Drilling unit up to 336 spindles

Contact us for product information, technical support or spare parts requests.