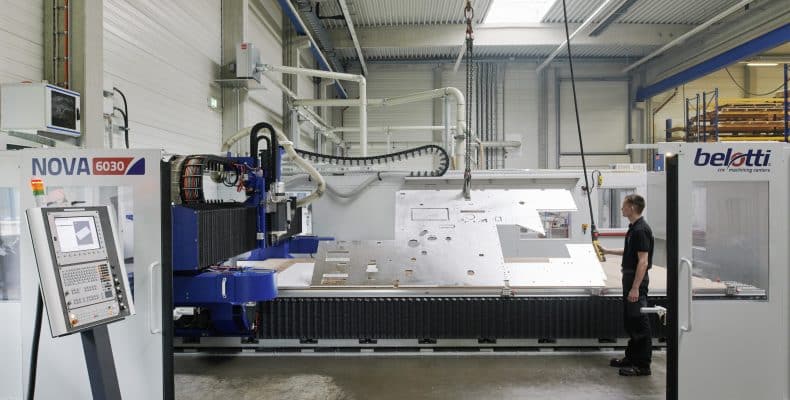

NOVA Series

Multi-axis machining centers for milling and trimming aluminium, technical plastic, and composite material plates.

The BELOTTI NOVA 3 and 5-axis machining centers are the result of the extensive experience gained over more than 40 years in the production of machines for milling aluminium, composite materials, and plastics.

The NOVA Series is the answer to the strong demand of leading industries in the packaging, aerospace, and automotive sectors.

Description

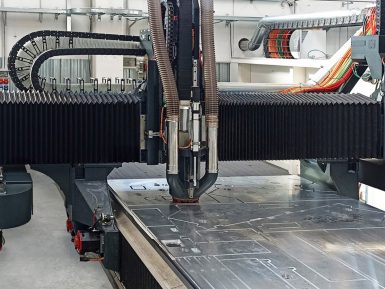

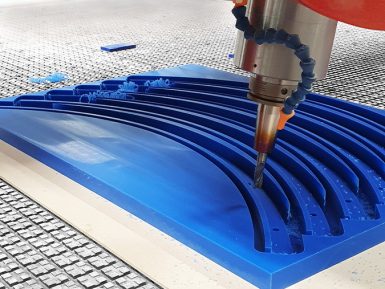

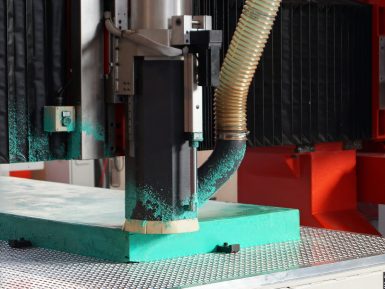

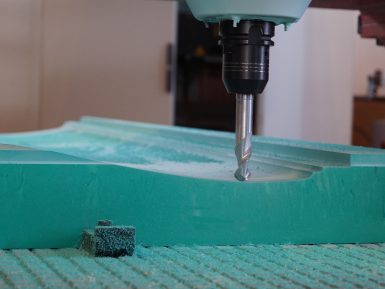

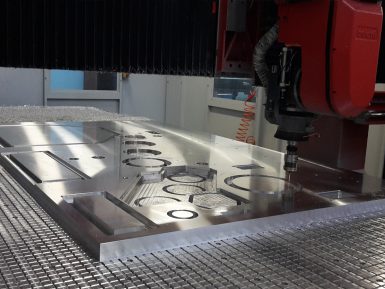

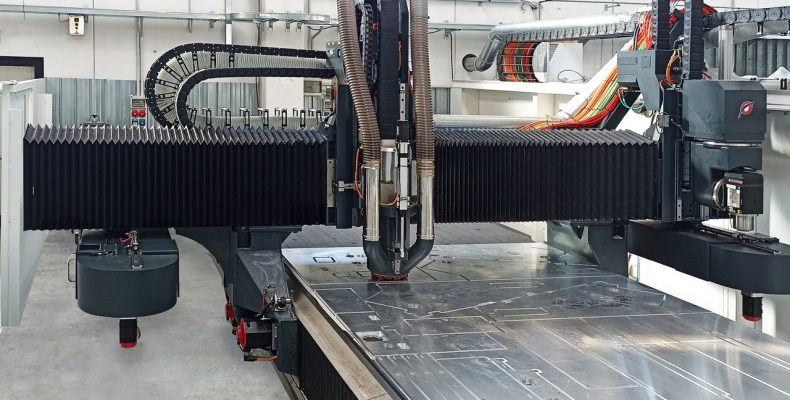

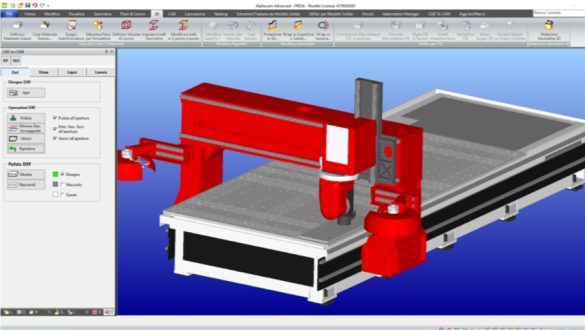

The Belotti NOVA CNC machining centers consist of a sturdy monolithic structure equipped with double slideways on both sides of the baseframe, which ensure maximum rigidity of the gantry during the machining process. The mobile bridge and the presence of a double motor on both sides (Dual Drive System) allow the processing of large workpieces, preserving the distinctive quality of the series. Available with both 3-axis and 5-axis heads, the NOVA CNC machining centers can process a variety of materials such as aluminium, light alloys, composites, plastics, and technical plastics, ensuring high performance provided by 15 or 30 kW electrospindles and top-of-the-line workpiece clamping systems. The optional, compact 5-axis head with axis clamping brakes and Heidenhain encoders, enables machining of parts with complex shapes while ensuring quality and precision. The ease and speed of tooling, thanks to laser part alignment systems, make the NOVA Series extremely high-performance: the result is a machining center that enables increased productivity and competitiveness. A specially designed and patented accessory is the CSRS (Caterpillar Stack Routing System), which addresses the need for stacked machining of multiple aluminium sheets.

Contact us for further technical information, sales requests or to schedule an on-line meeting.

Sectors

- Packaging

- Checking fixtures

- Aerospace

- Automotive

- Design and furniture

- Railway

- Marine

- Energy and building

Materials

- Aluminium panels

- Light alloys

- Technical plastic

- Plastic

- Composites

- Resins

Technical features

| Axis | X | Y | Z | C | A |

|---|---|---|---|---|---|

| Stroke | 2/3/4/5/6/10 m | 1,6/2/2,5/3 m | 0,3/0,5 m | +/- 270° | +/- 120° |

| Speed | 50 m/min | 30 m/min | 44 rpm | 40 rpm | |

| Spindle | From 15 kW up to 30 kW at 30.000 rpm max. | ||||

| CNC | Fanuc, Heidenhain, Siemens | ||||

| Tool change | From 12 to 60 positions, also with exchange arm | ||||

| Linear accuracy | < 0,009 mm/m for linear axes | ||||

| Rotary accuracy | +/- 12 arcsec for rotary axes | ||||

| Measurement system | Linear scales, 5 micron resolution | ||||

| Axis | X | Y | Z | C | A |

|---|---|---|---|---|---|

| Travels | 78/118/157/197/236/393″ | 63/79/118″ | 11.8/19.7″ | +/- 270° | +/- 120° |

| Rapids | 1,270 ipm | 762 ipm | 44 rpm | 40 rpm | |

| Spindle | From 20 HP up to 40 HP at 30,000 rpm max. | ||||

| CNC | Fanuc, Heidenhain, Siemens | ||||

| Tool change | From 12 to 60 positions, also with exchange arm | ||||

| Linear accuracy | ≤ 0,00035″ / 40″ for linear axes | ||||

| Rotary accuracy | +/- 12 arcsec for rotary axes | ||||

| Measurement system | Linear scales, 5 microns (0,0002″) resolution | ||||

Accessories

Linear scales

Direct incremental measuring system for all linear axes with pressurized, metal graduated scale.

Two models available:

- single section unit with glass optical scale for lengths up to 4 m.

- multi-section unit with steel optical scale for lengths from 4 m to 72 m. In comparison with the steel band version, this model is not affected by temperature variations.

Double motor

Aluminium vacuum table with MDF panel

Aluminium table on which MDF panels are screwed, especially designed for machining of aluminium plates.

The table is divided into 12 areas, with dimensions to be defined, that can be automatically managed by the CNC. It is equipped with vacuum electrovalves and preset vacuometers to check the minimum vacuum level on the part for safe clamping.

In case mechanical clamping is needed, the MDF panel can be removed.

Upon request, it will be possible to provide multiple rapid connections for vacuum clamping.

5-axis high performance head up to 22 kW

5-axis head with electrospindle, direct drive encoders and rotary axis pneumatic locking system. It can be used as a replacement for the 3-axis version or installed as a second independent 5-axis head (dual head solution).

Electronic suction hood for 3-axis head

Scraps suction hood used with 3-axis machining, electronically controlled.

In a range of 180 mm the electronic hood automatically adjusts its extension according to the real distance from the part.

The hood automatically retracts during the tool changer.

The dust suction hood performance may vary according to the part geometry, to the material and to the machining strategy.

Minimal lubrication system through the spindle

Centralized grease system, complete with pressure control and minimum level in the tank, which provides for the automatic lubrication of the moving parts. Lubrication is managed by NC in fully automatic mode and allows an extension of the life of the mechanical parts.

CSRS - Caterpillar Stack Routing System

CSRS is a special Belotti-patented device to apply on the NOVA 3-axis head, in order to have a constant, high-pressure compression on the tool zone during all the operations. This option is particularly suggested when machining multilayer stacked aluminium sheets.

The system in made of two independent bridges working simultaneously: the bridge no.1 is equipped with a 3-axes 30 kW spindle; the bridge no.2 is equipped with a mobile CSRS pressure foot – for milling operations – and with a fixed pressure foot – for removing tags operations. The two bridges work together for the machining of multi-sheet stack. In the event that bridge no. 2 is not required, the machine can be customized as a standard 3 axis CNC center.

MAIN ADVANTAGES:

- Preserving the stability

- Improving the finishings and the operating speed

- Solving possible coolant penetration issues

- Keeping the working area clean thanks to an efficient suction system that conveys the chips in a dedicated bin, simplifying the unloading process of the final pieces.

Contact us for product information, technical support or spare parts requests.