The 3 and 5 axis milling processes have seen an important growth in both application sectors and performance of its machining centers through continuous research.

Over the years Belotti has become a leading player in the production of cnc centers for the milling and trimming of materials such as plastics, composites, resins and light alloys.

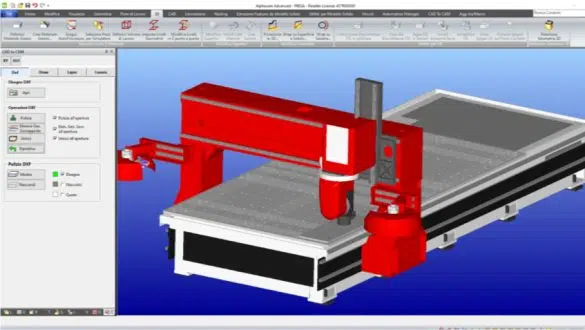

Using the latest generation of multi-axis machining centers: