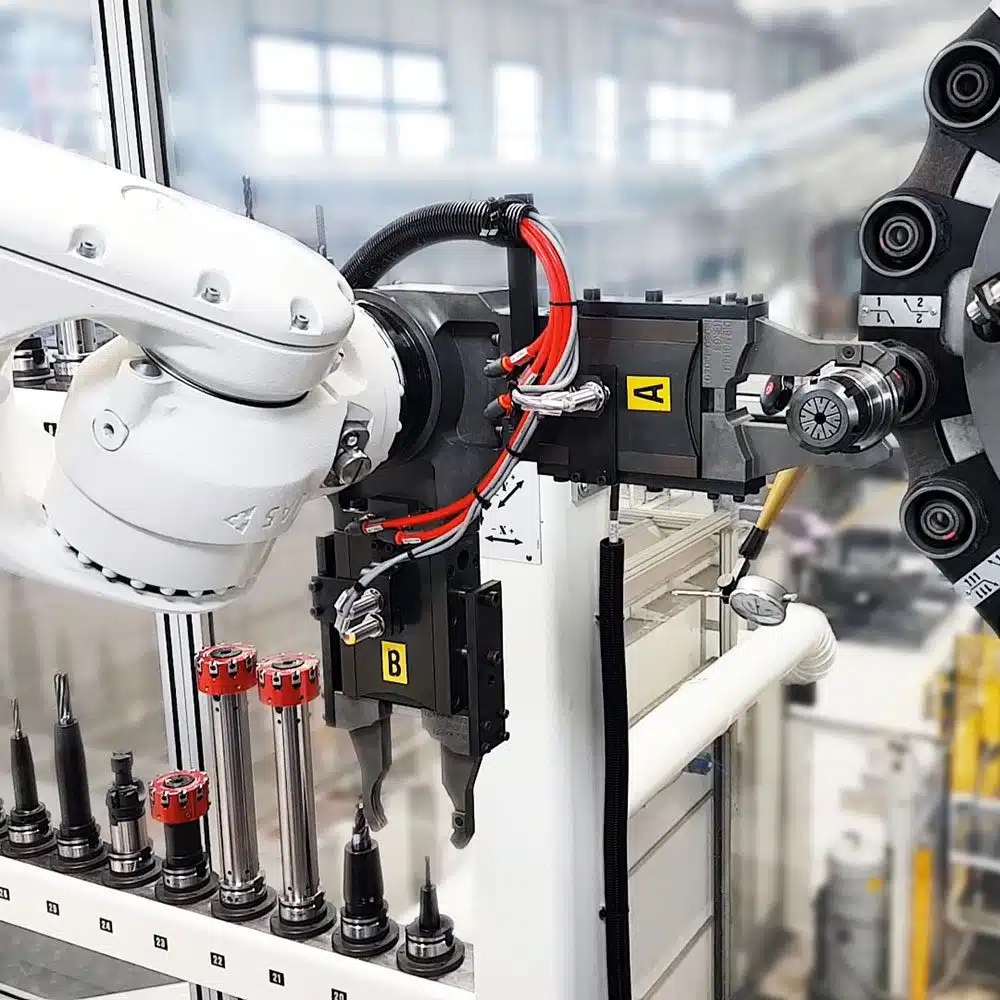

- CNC-Maschinen

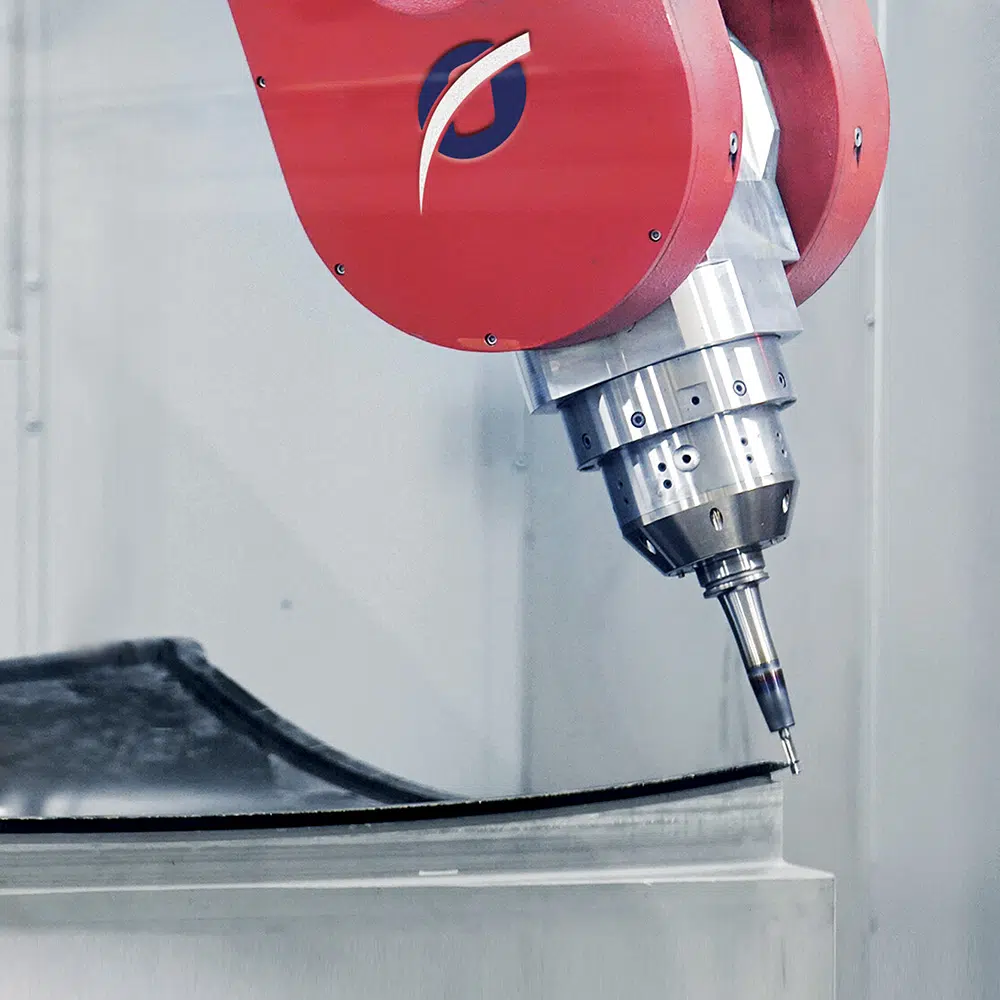

Maßgeschneiderte Lösungen für spezifische Anwendungsanforderungen:

- Fortschrittliche Technologien

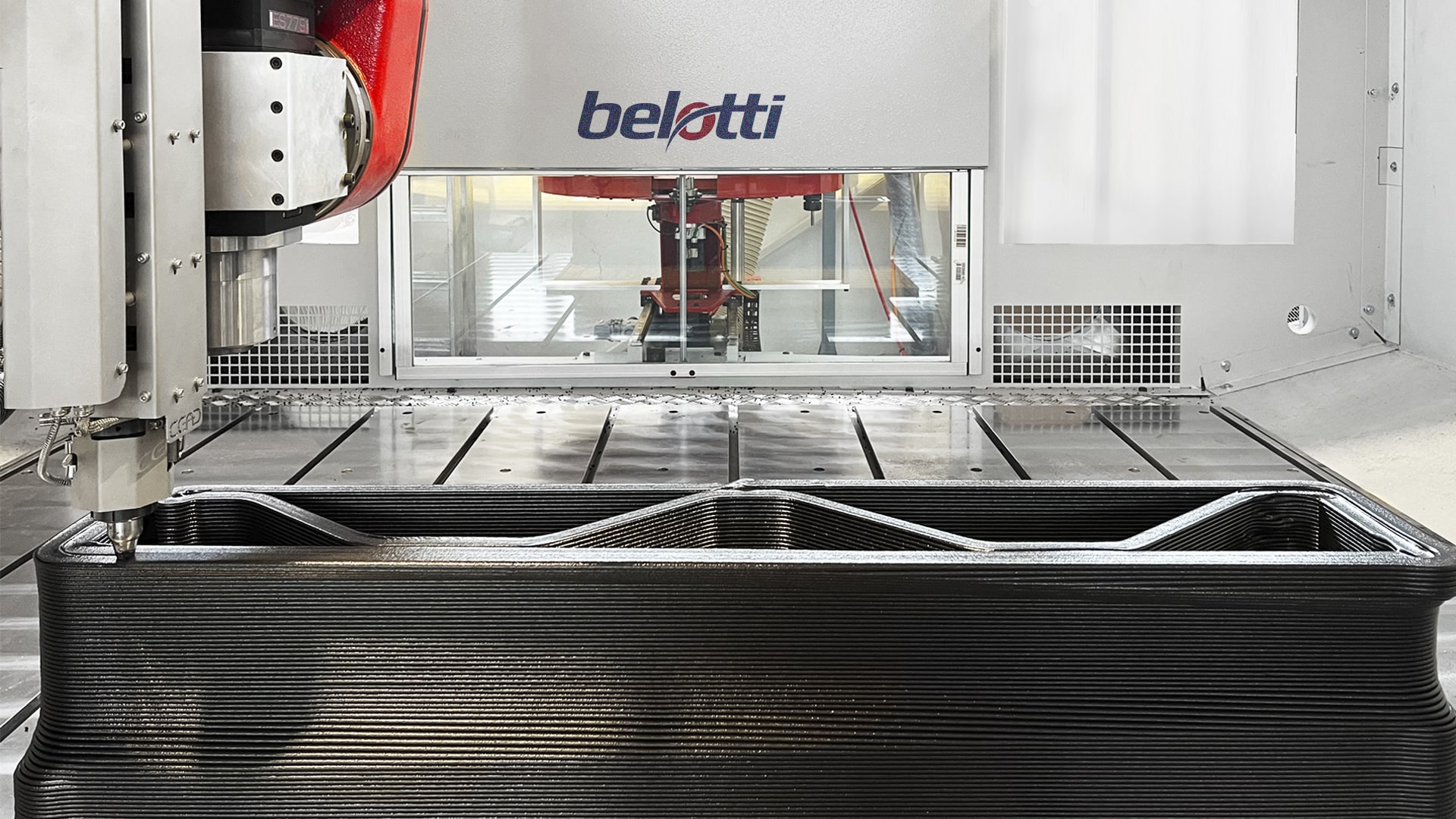

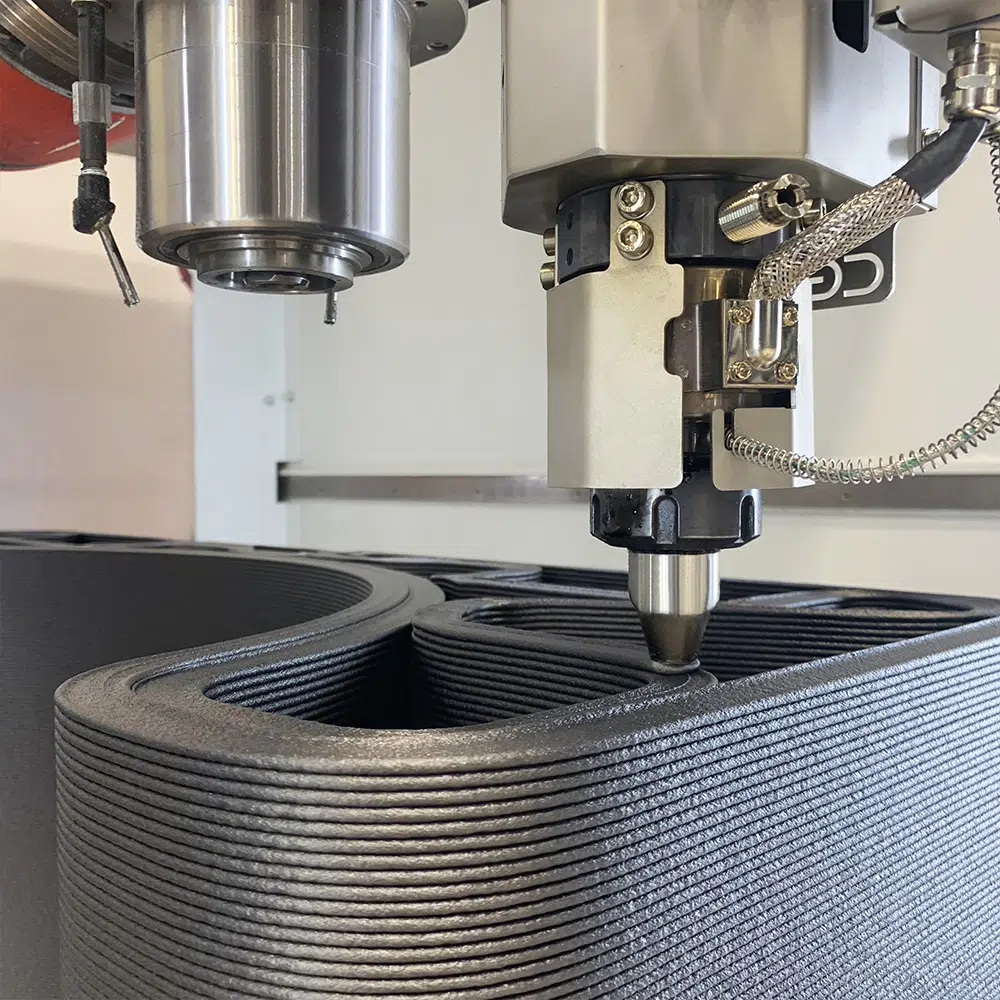

- Hi-Tech-Ausrüstung

- 3D-Drucken

- Software

- Die Materialien

Maßgeschneiderte Bearbeitungstechnologien für jede Art von Material

- Die Sektoren

CNC-Bearbeitungszentren und fortschrittliche Lösungen für verschiedene Industriebereiche

- Success Stories

-

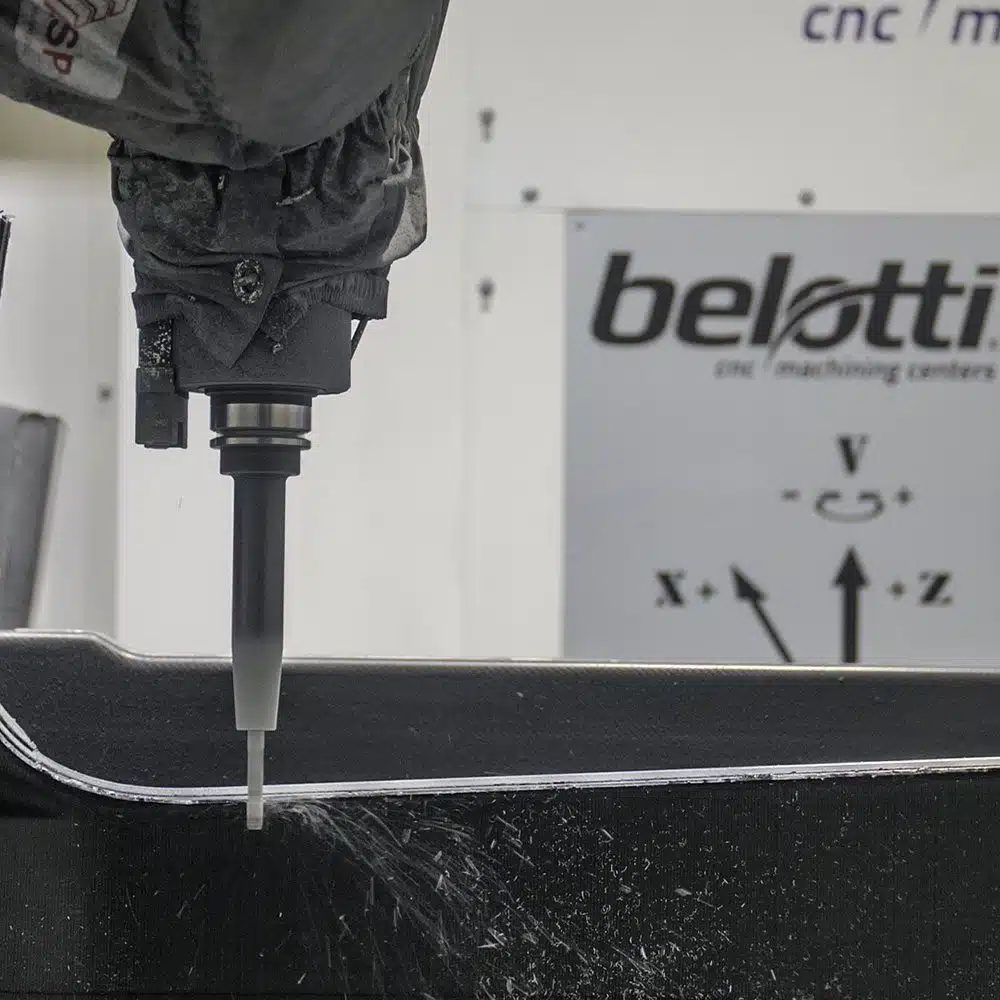

WASSERSTRAHL

Höchste Präzision und Geschwindigkeit für die Bearbeitung von Verbundwerkstoffen.

Erfahren Sie mehr -

MDL

5-Achsen-Hochgeschwindigkeitszentren für die Bearbeitung von Verbundwerkstoffen und Leichtmetalllegierungen.

Erfahren Sie mehr

Die ideale Lösung für die Automobil- und Luft- und Raumfahrtindustrie. -

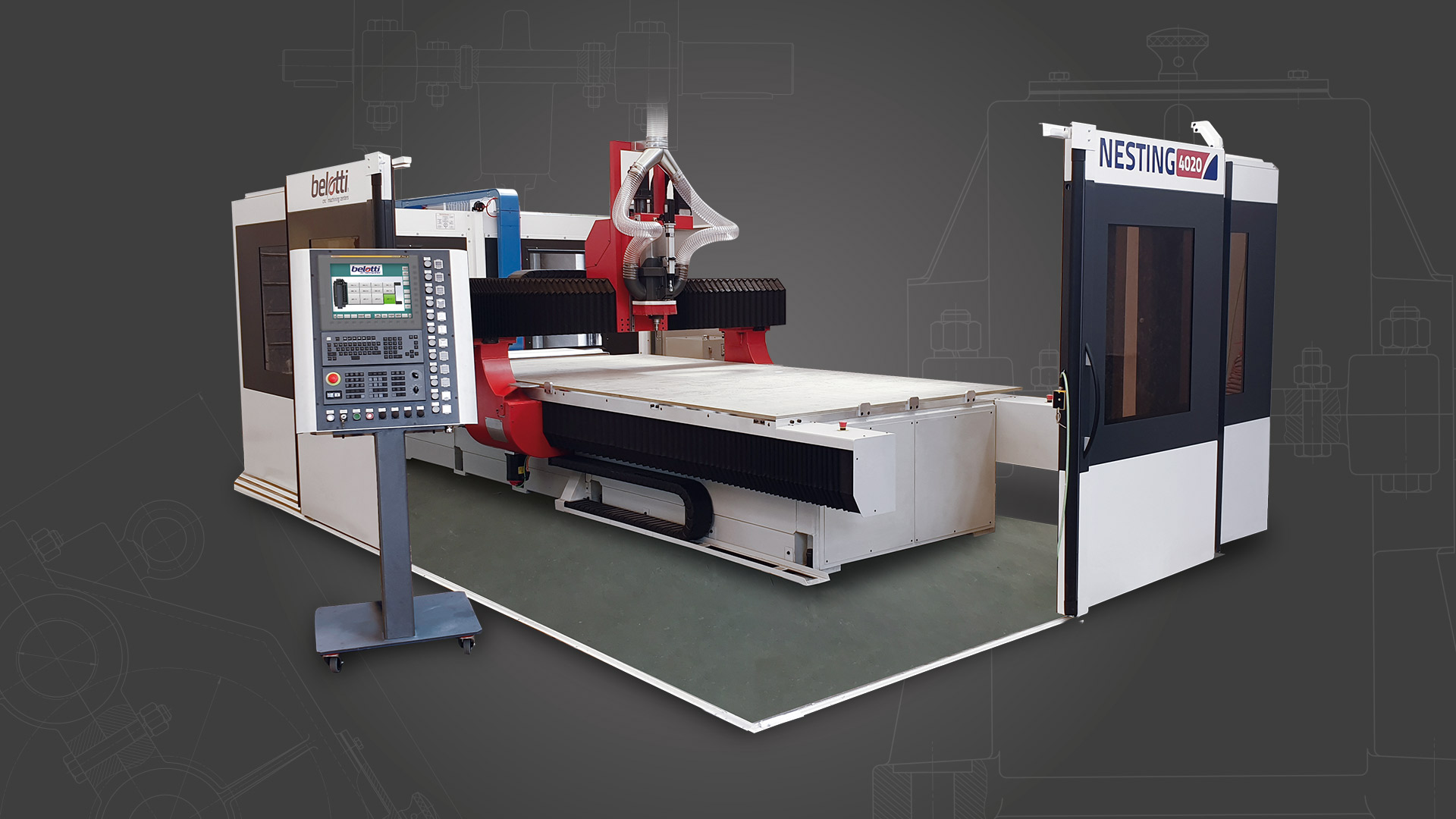

NESTING

Die neue kompakte und einfach zu programmierende Serie von CNC-Zentren zur Bearbeitung und Verschachtelung von Aluminium- und Kunststoffplatten

Erfahren Sie mehr -

-